|

Fujitsu Develops Technology for Measuring Magnetic Properties under Stress Using Piezoelectric Device

Will contribute to more precise large-scale simulations of magnetic fields to streamline designs, such as for electric-vehicle motors

TOKYO, Dec 08, 2016 - (JCN Newswire) - Fujitsu Laboratories Ltd. today announced the development of technology for measuring the magnetic properties of materials when force (stress) is applied. This will be vital to enabling more advanced large-scale simulations of the kinds of magnetic fields found in the motors of electric vehicles (EV).

EV engines, which have numerous operating conditions, such as their rotational speed, need to be prototyped and tested repeatedly under these different conditions. Computer simulations could help make the design process more efficient and increase motor performance, but the simulations need to be able to accurately model energy losses arising from the magnetic fields of different materials, which can change considerably when stress is applied. This creates a need for a technology that can accurately measure the effects of stress.

By attaching a piezoelectric device to an electromagnetic steel test plate to create various states of stress, Fujitsu Laboratories developed the world's first technology that measures the magnetic property called vector magnetic hysteresis(1) - which reduces motor efficiency - in the presence of stress.

Fujitsu Limited will be able to use this technology to obtain a wide variety of measurement data that are vital to the large-scale, multi-scale magnetic-field simulator(2) that it is currently developing. This technology promises to promote the design of high-efficiency electric motors with low energy loss, and the development of material informatics, which is the development of materials with computer simulations.

Details of this technology were presented at the Institute of Electrical Engineers of Japan's Joint Meeting on Magnetics & Linear Drive, opened December 5 in Nagasaki, Japan.

Development Background

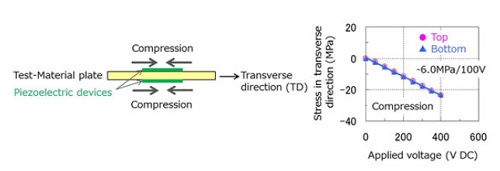

| | Figure 1: How the piezoelectric device applies stress to the test-material plate | | |

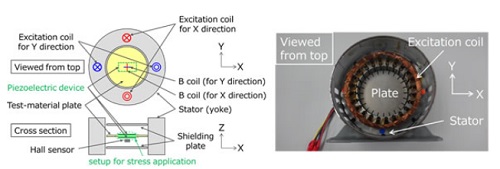

| | Figure 2: Compact instrument measures magnetic properties of materials with stress applied. A schematic (left) and an instrument photo (right) | | |

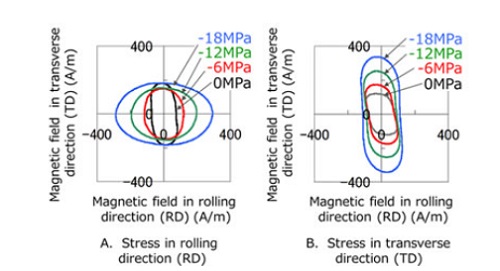

| | Figure 3: Vector magnetic hysteresis measured under compressive stress using this instrument | | |

Motors are said to account for some 40-50% of worldwide electric-power consumption. When motors are running, energy loss occurs due to the properties that the motor's constituent materials exhibit in relation to magnetism; improving the efficiency of all the electric motors in Japan by 1%, for example, would result in energy savings equivalent to the energy produced by one thermal-generation power plant. In addition, not only from an environmental perspective, but as electric motor-driven EV become more prevalent, there is a growing demand for technologies that can improve motor efficiency.

Issues

EV engines, which have numerous operating conditions, such as their rotational speed, need to be prototyped and tested repeatedly under these different conditions. Computer simulations could help make the design process more efficient and increase motor performance.

The materials used in electric motors undergo a process in manufacturing called shrink-fitting, in which they are joined using heat and force; this process creates stress inside the material that persists. Simulations need to be able to accurately model the energy loss arising from the magnetic properties of a material, but it is known that those magnetic properties can change significantly when stress is applied, so there is a need to be able to accurately measure the effects of stress. But because existing measuring devices for applying stress are large - about one meter square - and perform measurements on a large scale, a more compact and convenient measurement device that could gather a wide range of data more easily would be desirable.

About the Technology

Fujitsu Laboratories has developed the world's first technology that measures a magnetic property called vector magnetic hysteresis, using a piezoelectric device with a shape that can change with the application of voltage and that can produce force in a specific direction to flexibly control the stress on the material being measured (see Figures 1, 2, 3).

Key features of the technology are as follows:

1. Technology to apply uniform stress to test material being measured

With this technology, a piezoelectric device - which changes form when voltage is applied - is attached to the test material being measured, and by controlling the voltage applied to the piezoelectric device, the magnetic properties are measured while modulating the stress applied to the test material plate. By attaching the piezoelectric device to the test material being measured using an adhesive, direct stress is applied to the area being measured. Because the test-material plate is a thin sheet, piezoelectric devices can be mounted to both sides, and by applying an equal stress to both sides, the test material's warpage can be controlled. In this way, stress is applied uniformly and with fine control based on voltages to the entire area being measured.

Figure 1: How the piezoelectric device applies stress to the test-material plate

http://www.acnnewswire.com/topimg/Low_FujitsuMagnetic1281.jpg

2. Compact instrument measures magnetic properties of material with stress applied

The common motor, known as an induction motor, can generate an internal electric field. Fujitsu Laboratories developed a Round Rotational Single Sheet Tester (RRSST) that measures vector magnetic hysteresis using a common, compact induction motor. The instrument has a simple structure and is small, measuring 30 cm square. By incorporating a structure in which it was possible to apply stress to the test materials and equipping it to the measuring instrument, Fujitsu Laboratories was able to easily measure vector magnetic hysteresis under a variety of stress conditions. This marks the world's first time that it was possible to measure vector magnetic hysteresis of stress conditions applied by a piezoelectric device. This technology was developed in collaboration with Professor Tetsuji Matsuo of Kyoto University.

Figure 2: Compact instrument measures magnetic properties of materials with stress applied. A schematic (left) and an instrument photo (right)

http://www.acnnewswire.com/topimg/Low_FujitsuMagnetic1282.jpg

Figure 3: Vector magnetic hysteresis measured under compressive stress using this instrument

http://www.acnnewswire.com/topimg/Low_FujitsuMagnetic1283.jpg

Results

This newly developed technology is capable of obtaining a variety of measurements needed to implement accurate magnetic-field simulations that account for stress applied to materials. Implementing accurate magnetic-field simulations promises to greatly accelerate the development process of EV motors, and, for example, to reduce the number of prototypes - each of which incur high costs and a great many man hours - needed to develop such equipment, from the current figure of around five to only one or two.

Future Plans

Fujitsu is developing FUJITSU Manufacturing Industry Solution EXAMAG LLG Simulator(3), magnetic-field simulation software package that uses massively parallel computation, and is currently working on next-generation magnetic-field simulations that can model the vector magnetic hysteresis properties of magnetic materials.

Fujitsu Laboratories plans to continue refining the capabilities for measuring vector magnetic hysteresis and will move forward on work on gathering different kinds of measurements, with the goal of incorporating the benefits of this technology into the next version of EXAMAG LLG Simulator being developed at Fujitsu and due out in 2018. This technology also promises to advance material informatics, which uses computer simulations in material development, and promises to contribute to less wasted energy as more efficient motors gain widespread adoption.

(1) Vector magnetic hysteresis

A quality that expresses the relationship between a rotational magnetic-field vector and a magnetic-flux density vector in magnetized materials. This expresses a property called magnetic hysteresis, which is affected not only by the strength of a current magnetic field, but also by past history.

(2) Large-scale, multi-scale magnetic-field simulator

By combining Fujitsu's and Fujitsu Laboratories' extensive experience in massively parallel computing with micro-magnetics techniques that analyze magnetic states in a magnetic material on a fine-grained level, and with finite-element analysis, a numerical analysis technique, this simulator is able to analyze magnetic fields with complex shapes over a range of scales from macro to micro.

(3) FUJITSU Manufacturing Industry Solution EXAMAG LLG Simulator

"Fujitsu Releases New Version of EXAMAG LLG Simulator, Magnetic-Field Simulation Software," (press release dated March 24, 2015: http://www.fujitsu.com/global/about/resources/news/press-releases/2015/0324-01.html)

About Fujitsu Laboratories

Founded in 1968 as a wholly owned subsidiary of Fujitsu Limited, Fujitsu Laboratories Ltd. is one of the premier research centers in the world. With a global network of laboratories in Japan, China, the United States and Europe, the organization conducts a wide range of basic and applied research in the areas of Next-generation Services, Computer Servers, Networks, Electronic Devices and Advanced Materials. For more information, please see: http://www.fujitsu.com/jp/group/labs/en/.

Contact:Fujitsu Laboratories Ltd.

Monozukuri Technologies Laboratory

E-mail: vec-hys@ml.labs.fujitsu.com

Fujitsu Limited

Public and Investor Relations

Tel: +81-3-3215-5259

URL: www.fujitsu.com/global/news/contacts/

Source: Fujitsu Ltd

Sectors: Electronics

Copyright ©2024 JCN Newswire. All rights reserved. A division of Japan Corporate News Network. |

Latest Press Release

UNIQLO Sponsors KAWS + Warhol Exhibition Tour, Starting in Pittsburgh

Apr 25, 2024 09:00 JST

|

Mitsubishi Power Begins Commercial Operation of Seventh M701JAC Gas Turbine in Thailand GTCC Project; Achieves 75,000 AOH To-Date

Apr 24, 2024 17:19 JST

|

MC and Denka Sign J/V Agreement in Fullerene Business

Apr 24, 2024 17:02 JST

|

Mitsubishi Motors Posts Record Sales in the Philippines in FY2023

Apr 24, 2024 13:56 JST

|

NEC Develops High-speed Generative AI Large Language Models (LLM) with World-class Performance

Apr 24, 2024 13:25 JST

|

Fujitsu SX Survey reveals key success factors for sustainability

Apr 23, 2024 10:25 JST

|

Fujitsu and METRON collaborate to drive ESG success: slashing energy costs, boosting productivity with new manufacturing industry solutions

Apr 22, 2024 16:09 JST

|

NEC Strengthens Commitment to Space Industry with Investment in Seraphim Space Venture Fund II

Apr 22, 2024 15:09 JST

|

Soft Space Launches the First and Only JCB Payment Gateway in Malaysia

Apr 22, 2024 15:00 JST

|

TOYOTA GAZOO Racing takes a one-two in Croatian thriller

Apr 22, 2024 10:47 JST

|

First-ever Mazda CX-80 Crossover SUV Unveiled in Europe

Apr 19, 2024 13:50 JST

|

Fujitsu develops technology to convert corporate digital identity credentials, enabling participation of non-European companies in European data spaces

Apr 19, 2024 10:17 JST

|

Mitsubishi Heavy Industries and NGK to Jointly Develop Hydrogen Purification System from Ammonia Cracking Gas

Apr 18, 2024 17:01 JST

|

Toyota Launches All-New Land Cruiser "250" Series in Japan

Apr 18, 2024 13:39 JST

|

Fujitsu and Oracle collaborate to deliver sovereign cloud and AI capabilities in Japan

Apr 18, 2024 11:14 JST

|

Eisai: Research on Treatments for Alzheimer's Disease Based on Its Pathological Mechanisms Recieves Award for Science and Technology (Research Category)

Apr 18, 2024 10:53 JST

|

All-New Triton Confirmed as First Double-Cab Pickup Truck to Achieve 2024 Five-Star ANCAP Safety Rating

Apr 18, 2024 09:22 JST

|

Eisai's Antiepileptic Drug Fycompa Injection Formulation Launched In Japan

Apr 17, 2024 16:17 JST

|

Honda Unveils Next-generation EV Series for China

Apr 17, 2024 12:15 JST

|

Lexus presents Time at the 2024 Milan Design Week

Apr 16, 2024 18:49 JST

|

More Latest Release >>

|