|

Mitsubishi Shipbuilding Marine SOx Scrubber System "DIA-SOx" Installation Completed Onboard 22 Ships Year-to-Date

Successfully Completed as Scheduled through Remote Commissioning

- Rectangular tower R Series installed on container ships and cylindrical tower C Series on large oil tankers and LPG carriers

- Installation works conducted in China and Singapore, and approved by classification societies after sea trials

TOKYO, Sep 04, 2020 - (JCN Newswire) - DIA-SOx that the marine SOx scrubbers produced by Mitsubishi Shipbuilding Co., Ltd., a part of Mitsubishi Heavy Industries (MHI) Group, have been successfully installed on 22 ships of 3 ship types(1) during the last 8 months from the beginning of this year. Whilst the infection of COVID-19 is continuing its spread across the world, Mitsubishi Shipbuilding successfully enabled to complete the installations as scheduled through remote commissioning conducted via close communication and cooperation with the engineers of its local partners in China and Singapore respectively.

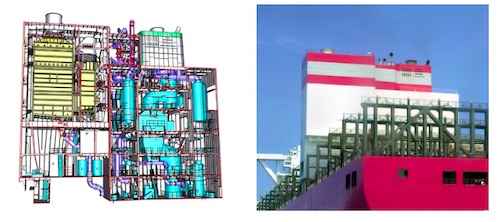

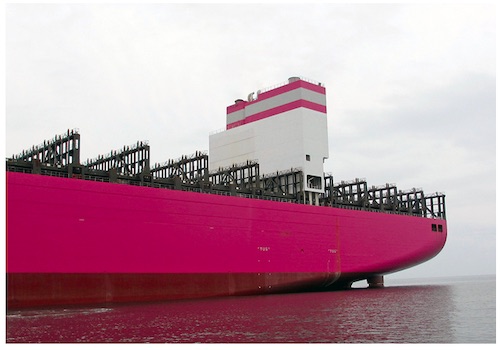

| | Arrangement of a scrubber onboard a 14,000 TEU container ship (left), and exterior after installation (right) | | |

| | | |

The line-up of DIA-SOx consists of the R Series and C Series. The rectangular tower design of the R Series is the most suitable for container ships and its multi-stream configuration can simultaneously with 1 tower treat exhaust gas discharged from multiple engines, including the large main engine. Moreover, its simplified configuration helps the ship crews to conduct the maintenance work easier. The C Series with cylindrical tower design also utilizes the multi-stream configuration, offering high flexibility that can be easily installed onboard various types of the ships.

Mitsubishi Shipbuilding also provides retrofit engineering for installation of both types of scrubbers, supporting customers to increase efficiency and improve reliability of their retrofitting projects. For 14,000 TEU (Twenty-foot Equivalent Units) container ships for which Mitsubishi Shipbuilding provided engineering services not only scrubber systems, the scrubber tower was installed in the built-in casings on the port side of the existing funnel, and therefore the scrubber system was installed without reducing container loading capacity, which is one of the advantages of the rectangular tower shape of the R Series (see pictures).

Those systems, after the verification by sea trials, got approval from Nippon Kaiji Kyokai (ClassNK), Lloyd's Register (LR), American Bureau of Shipping (ABS), and other classification societies.

As from January 1, 2020, the worldwide regulation of maximum sulfur content for fuel oil other than Emission Control Areas (ECA) has been strengthened to below 0.50% m/m (mass percent) from the previous standard of 3.50% m/m. Further, after March 2020, ships have been prohibited even from retaining onboard fuel oil with a sulfur content exceeding regulation levels. Nevertheless, the ships, approved by the relevant flag states as fitted with SOx scrubbers, can continue to use the less expensive high sulfur content fuel oil while operating the scrubbers.

Mitsubishi Shipbuilding will continue not only providing marine scrubbers, but also as an engineering company offering superior engineering services for scrubber installation to fully meet customers' needs and requests, regardless whether for retrofittings or newbuildings, for ships built by MHI or others, in order to contribute to the further development of ocean transport, and to reduce the environment load that is increasing on a global scale.

(1) R Series: 20,000 TEU container ships (5 ships), 14,000 TEU container ships (8 ships), container ships 10,000 TEU or less (5 ships)

C Series: Large oil tankers with dead-weight capacity of 300,000 tonnes (2 ships), liquefied petroleum gas (LPG) carriers (2 ships)

Source: Mitsubishi Heavy Industries, Ltd.

Sectors: Marine & Offshore

Copyright ©2026 JCN Newswire. All rights reserved. A division of Japan Corporate News Network. |