|

Fujitsu Launches iCAD SX V8, 3D CAD Processing 3 Million Parts in 0.2 Seconds

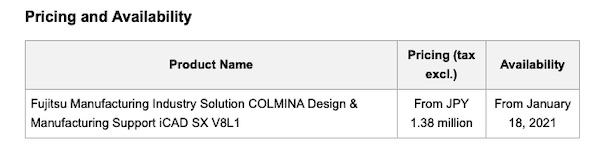

TOKYO, Nov 16, 2020 - (JCN Newswire) - Fujitsu today announced the Japan launch of iCAD SX V8L1, the latest version of the 3D CAD software Fujitsu Manufacturing Industry Solution COLMINA Design & Manufacturing Support iCAD SX(1) for machinery design, which is powered by the world's fastest 3D CAD engine. Sales will begin November 16th, with expansion across the globe in stages at a later date.

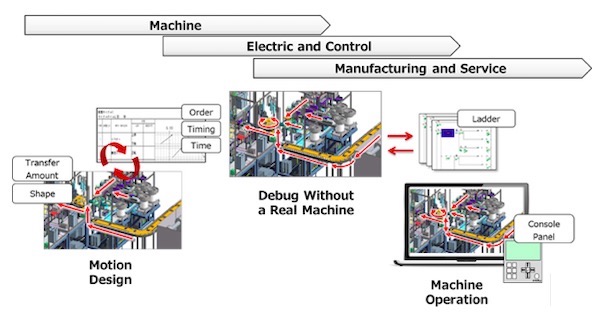

| | Design study and verification of motion utilizing 3D data | | |

| | | |

This solution greatly enhances current high-speed processing performance by improving memory access processing and can handle large-scale 3D data consisting of as many as 3 million parts in the design examination and verification of machine equipment. It delivers processing performance that arrives at the result of trial and error by the designer in 0.2 seconds. Fujitsu has additionally developed and implemented new design functions that allow mechanical, electrical, and control designers to keep and utilize operation and manufacturing information, as well as functions that enable the use of 3D data in manufacturing and maintenance services.

This enables the smooth sharing of information between departments in a digital environment by connecting common 3D data from design upstream to manufacturing and maintenance services, contributing to the reduction of lead time in the manufacturing industry in the "new normal" era.

Background

In the manufacturing industry, shortening the development period and reducing the number of manufacturing processes has been a challenge for many years. Design departments need to speed up product development and improve quality, while manufacturing departments are also expected to improve the efficiency of processing and assembly operations. In addition, the COVID-19 pandemic has led to the promotion of the digital transformation of design processes, which are the upstream of manufacturing. Along with this new normal way of working, collaboration between design, manufacturing, and services utilizing digital data also represents an area of robust and growing demand. In order to realize these requirements, it is necessary to have 3D CAD that can handle large-scale data such as equipment, facility lines, and entire plants, and can process various design information at ultra-high speed even if it is stored in one 3D data.

Product Features

1. Delivers ultra-fast response time of 0.2 seconds for 3 million parts

By improving memory access processing and increasing the processing speed for very large data, the number of parts that can be handled in three dimensions has been tripled. This makes it possible to design ultra-large-scale semiconductor manufacturing equipment, facility lines, and entire plants smoothly in 3D, even if design information is stored in 3D data, without concern for the loss of response.

2. Efficient design study and verification by accumulating and utilizing operation information of 3D device models

The movement information such as movement amount, order of movement, and timing of the 3D device model, which was previously recorded in memos or memorized by designers, can be directly added to the 3D data from the initial stage of design, and the movement, process, and cycle time can be examined while confirming the positional relationship with peripheral parts. In addition, by utilizing the stored 3D data as it is, real machine-less debugging in control design is possible. As a result, quality can be built up in the design phase, and the cause of failure can be identified in a short period of time in the event of actual equipment trouble.

3. Supports 3D manufacturing with new functions that enable the accumulation of manufacturing information

Fujitsu has added a new function that allows users to store and utilize manufacturing information whenever they decide, including data on manufacturing conditions and assembly instructions that are determined early in the design process. This makes it possible to calculate the cost of a part using a 3D equipment model and machining information, and to perform 3D inspection(2) to check the consistency of surface roughness(3) and mating tolerance(4) between parts. In manufacturing and maintenance services, the procedures for assembly and replacement of consumable parts can be studied in 3D data in advance, reducing the time for trial and error in the field and shortening lead time. In addition, when assembling machinery at an overseas plant, engineers in Japan can perform work remotely without traveling internationally because they can check the assembly procedure of 3D data at the plant.

Fujitsu will continue to support Digital Transformation (DX) in the manufacturing industry in fulfillment of its mission for its manufacturing brand, COLMINA: "Bringing innovation to manufacturing through the delivery of services that are global, open, and rapid that help to realize DX." Fujitsu's commitment to this mission for its COLMINA brand will ultimately allow for the creation of new value and enhance competitiveness in the manufacturing industry as a whole.

Sales Target

20,000 licenses in fiscal 2021 (Fujitsu's fiscal year ends March 31).

(1) Fujitsu Manufacturing Industry Solution COLMINA Design & Manufacturing Support iCAD SX Please note that outside the Japanese market the product is officially referred to as Fujitsu Manufacturing Industry Solution COLMINA Design & Manufacturing Support FJICAD SX.

(2) 3D inspection To perform an inspection work for finding design mistakes by looking at shapes and dimensions in a 2D drawing using 3D data.

(3) Surface roughness A numerical representation of the state of the machined surface of a part (unevenness).

(4) Mating tolerance A numerical indication of the degree of fit between a shaft and a hole.

Source: Fujitsu Ltd

Sectors: Enterprise IT

Copyright ©2026 JCN Newswire. All rights reserved. A division of Japan Corporate News Network. |