|

EEJA and Tokyo U Achieve Simultaneous Formation of Contact Electrodes for p-Type and n-Type Organic Semiconductor Crystals Using the Plating Method

Enabling the atmospheric formation of low-contact resistance electrodes and high-mobility high-performance organic transistors that are among the best in the world

TOKYO, Mar 16, 2015 - (JCN Newswire) - Tanaka Holdings, Co., Ltd. (Head office: Chiyoda-ku, Tokyo; President & CEO: Akira Tanae) announced today that Electroplating Engineers of Japan, Ltd. (Plant and Office: Hiratsuka-shi, Kanagawa; President and CEO: Koichiro Tanaka; EEJA), which operates the Tanaka Precious Metals Group's plating business, together with Professor Junichi Takeya of the University of Tokyo's Graduate School of Frontier Sciences, has achieved the world's first success in the development of technology for the simultaneous formation of contact electrodes for p-type and n-type*1 Organic-semiconductor Field Effect Transistors ("OFET," hereafter) using an electroless plating process.

| | Gold and silver hybrid structure |

By using an electroless gold plating process with silver nanoparticles as a catalyst for an organic semiconductor, this technology enables the formation in the atmosphere of top contact-type OFET (figure 1)*2 contact electrodes without the use of a vacuum environment, which requires large-scale equipment. As opposed to metallic ink, which has the same atmospheric contact formation, this technology realizes the formation of a high-performance OFET as there is little damage to the organic semiconductor, and the performance of the high-mobility*3 organic semiconductor is not affected. Also, due to the emergence of high-performance n-type semiconductor materials in recent years, more advanced organic electronic devices can now be formed at a low-cost thanks to the simultaneous formation of contact electrodes for p-type and n-type OFET mixed circuits, for which development is speeding up.

For p-type organic semiconductors, the contact resistance of the contact electrodes using this technology is 0.1Kiloohm-cm or less, which is the lowest value currently on record in terms of the contact resistance of organic semiconductor contact electrodes formed in the atmosphere. The atmospheric formation of a high-performance OFET (Figure 2) with low-contact resistance electrodes and high-mobility that are among the top levels in the world is achieved by combining the merits of this technology with those of high-performance coating-type organic semiconductors developed by Professor Takeya which can be formed atmospherically. This result enables the atmospheric formation of organic electronic devices with high-speed drives, and it enables the production of high functionality electronic devices using printed electronics*4.

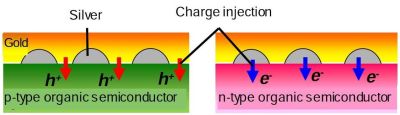

This technology is a process for the formation of contact electrodes with a gold-silver hybrid structure, which is achieved by applying a silver catalyst solution for plating that includes silver nanoparticles to an organic semiconductor crystal, after which a gold coating is applied to the substrate by immersing it in an electroless gold plating solution so that the gaps between the silver grains are filled with gold. This enables the single-process formation of low-contact resistance contact electrodes for p-type organic semiconductors, which facilitate a charge injection from gold, and n-type organic semiconductors, which facilitate a charge injection from silver (Figure 3).

EEJA will announce the research findings relating to this technology at the 62nd Jpan Society of Applied Physics Spring Meeting, to be held between March 11 and March 14 at Tokai University, Shonan Campus (Hiratsuka-shi, Kanagawa).

Background to this technology

OFET is a transistor that uses an organic semiconductor, which means that - among other characteristics unique to organic materials - it can be formed at low-temperatures, is lightweight and is flexible. The high-performance of organic semiconductor materials has progressed rapidly in recent years, and materials are being developed with double-digit increases over the figure that was thought to be the limit for the mobility of organic semiconductors. The pioneering findings of Professor Takeya's research group make possible the atmospheric formation of high-mobility organic semiconductors, which is expected to increase the fields of use for organic semiconductors.

While there are several methods for the formation of OFET contact electrodes, they all suffer from such issues as requiring a vacuum environment and causing damage to organic semiconductors. For example, thin film electrodes can be formed uniformly using the vacuum deposition method, but the equipment used to create a vacuum environment is incredibly expensive, and the loss of materials is huge. Also, while electrode formation in the atmosphere is possible using metallic ink and metallic paste, it also requires the inclusion of organic solvents, high-temperature sintering, and hardening by means of ultra-violet rays, which damages the organic semiconductor, and does not achieve sufficient results as a transistor.

This is why, in September 2014, EEJA together with Professor Takeya's research group jointly developed plating-process contact electrode formation technology for p-type organic semiconductors. In order to stably form electrodes for organic semiconductor crystals, EEJA developed new gold nanoparticles as an electroless plating catalyst. The contact resistance of the contact electrodes formed using this technology is 0.7Kiloohm-cm, which is a remarkably low contact resistance for atmospheric formation contact electrodes. Also, Professor Takeya's research group developed a coating-type organic semiconductor that could be formed in a short time in the atmosphere with a large-surface thin film with uniform crystal orientation, and a mobility (which is the deciding factor in the performance of semiconductors) that greatly surpasses that of conventional organic semiconductors at 10cm2/Vs or more.

Contributing to the development of new devices with OFET application - the development for the future

Because OFET has the characteristics of being printable, lightweight and flexible, we anticipate such device developments as flexible displays and disposable RFID (automatic wireless identification) tags. Currently, development is mainly progressing for devices that use p-type organic semiconductors, but the development of all-flexible displays and wearable computers, which require advanced circuitry and bendable driver ICs, also requires p-type and n-type OFET mixed circuitry and both OFETs must operate at high speeds. This jointly developed technology contributes to technical innovation in connection to organic electronic devices. EEJA will continue to find further solutions for utilization in organic electronic devices.

*1 p-type organic semiconductors and n-type organic semiconductors

Organic compounds crystalized with uniform crystal orientation acquire the characteristics of a semiconductor. By injecting a positive charge, the electrified object is referred to as a p- (positive) type organic semiconductor. By injecting a negative charge, the electrified object is referred to as an n- (negative) type organic semiconductor. The metal that is easier to be injected with a charge varies depending on whether it is a p-type or n-type.

*2 Top contact-type OFET

This is an organic transistor where the contact electrodes are located on the semiconductor crystal. This structure enables a drive with a higher speed than that of OFETs with other structures. However, because the electrodes are formed after forming the organic semiconductor crystal, the organic semiconductor is easily damaged, and contact electrodes are difficult to form.

*3 Mobility

This signifies the ease of movement for the charge within the semiconductor. Electronic devices that carry out complex processes require a higher mobility. Until a few years ago, the mobility of organic semiconductors was generally about 0.1cm2/Vs, but materials have been developed in recent years with a mobility of 10cm2/Vs or more.

*4 Printed electronics

This is a technology for the atmospheric formation of electronic circuits and devices on substrates using printing technology and so on.

Press release: http://www.acnnewswire.com/clientreports/598/0310_EN.pdf

Tanaka Holdings Co., Ltd. (Holding company of Tanaka Precious Metals)

Headquarters: 22F, Tokyo Building, 2-7-3 Marunouchi, Chiyoda-ku, Tokyo

Representative: Akira Tanae, President & CEO

Founded: 1885

Incorporated: 1918

Capital: 500 million yen

Employees in consolidated group: 3,562 (FY2013)

Net sales of consolidated group: 967.6 billion yen (FY2013)

Main businesses of the group: Manufacture, sales, import and export of precious metals (platinum, gold, silver, and others) and various types of industrial precious metals products. Recycling and refining of precious metals.

Website: http://www.tanaka.co.jp/english (Tanaka Precious Metals), http://pro.tanaka.co.jp/en (Industrial products)

Electroplating Engineers of Japan Ltd. (EEJA)

Head office: 5-50 Shinmachi, Hiratsuka-shi, Kanagawa

Representative: Koichiro Tanaka, President & CEO

Established: 1965

Capital: 100 million yen

Employees: 94 (FY2013)

Sales: 23,360 million yen (FY2013)

Areas of Business:

1. Development, production, sales and export of Sel-Rex precious metal and base metal plating

solutions, additives, and surface processing-related chemicals through a technical

partnership with the Enthone Group

2. Development, production, sales, and export of plating equipment

3. Import and sales of plating-related products

Website: http://www.eeja.com/

About the Tanaka Precious Metals

Established in 1885, the Tanaka Precious Metals has built a diversified range of business activities focused on the use of precious metals. On April 1, 2010, the group was reorganized with Tanaka Holdings Co., Ltd. as the holding company (parent company) of the Tanaka Precious Metals. In addition to strengthening corporate governance, the company aims to improve overall service to customers by ensuring efficient management and dynamic execution of operations. Tanaka Precious Metals is committed, as a specialist corporate entity, to providing a diverse range of products through cooperation among group companies.

Tanaka Precious Metals is in the top class in Japan in terms of the volume of precious metal handled, and for many years the group has developed and stably supplied industrial precious metals, in addition to providing accessories and savings commodities utilizing precious metals. As precious metal professionals, the Group will continue to contribute to enriching people's lives in the future.

The eight core companies in the Tanaka Precious Metals are as follows.

- Tanaka Holdings Co., Ltd. (pure holding company)

- Tanaka Kikinzoku Kogyo K.K.

- Tanaka Kikinzoku Hanbai K.K.

- Tanaka Kikinzoku International K.K.

- Tanaka Denshi Kogyo K.K.

- Electroplating Engineers of Japan, Limited

- Tanaka Kikinzoku Jewelry K.K.

- Tanaka Kikinzoku Business Service K.K.

Press inquiries

Global Sales Dept., Tanaka Kikinzoku International K.K. (TKI)

https://www.tanaka.co.jp/support/req/ks_contact_e/index.html

Source: Tanaka Holdings Co., Ltd.

Sectors: Metals & Mining, Design Process, Electronics, Science & Research

Copyright ©2024 JCN Newswire. All rights reserved. A division of Japan Corporate News Network. |

Latest Release

First-ever Mazda CX-80 Crossover SUV Unveiled in Europe

Apr 19, 2024 13:50 JST

|

Fujitsu develops technology to convert corporate digital identity credentials, enabling participation of non-European companies in European data spaces

Apr 19, 2024 10:17 JST

|

Mitsubishi Heavy Industries and NGK to Jointly Develop Hydrogen Purification System from Ammonia Cracking Gas

Apr 18, 2024 17:01 JST

|

Toyota Launches All-New Land Cruiser "250" Series in Japan

Apr 18, 2024 13:39 JST

|

Fujitsu and Oracle collaborate to deliver sovereign cloud and AI capabilities in Japan

Apr 18, 2024 11:14 JST

|

Eisai: Research on Treatments for Alzheimer's Disease Based on Its Pathological Mechanisms Recieves Award for Science and Technology (Research Category)

Apr 18, 2024 10:53 JST

|

All-New Triton Confirmed as First Double-Cab Pickup Truck to Achieve 2024 Five-Star ANCAP Safety Rating

Apr 18, 2024 09:22 JST

|

Eisai's Antiepileptic Drug Fycompa Injection Formulation Launched In Japan

Apr 17, 2024 16:17 JST

|

Honda Unveils Next-generation EV Series for China

Apr 17, 2024 12:15 JST

|

Lexus presents Time at the 2024 Milan Design Week

Apr 16, 2024 18:49 JST

|

Mitsubishi Corporation Announces Participation in a DAC Project in Louisiana, USA

Apr 16, 2024 14:36 JST

|

New circuit challenge for TOYOTA GAZOO Racing

Apr 15, 2024 17:21 JST

|

TOYOTA GAZOO Racing back on asphalt for Croatian challenge

Apr 12, 2024 19:36 JST

|

Heidelberg Materials North America Announces Latest Milestone in Edmonton CCUS Project

Apr 12, 2024 14:39 JST

|

MHIAEL Completes Expansion of the its Nagasaki Plant for Manufacture of Aero Engine Combustors

Apr 11, 2024 18:08 JST

|

Mitsubishi Shipbuilding Acquires Approval in Principle (AiP) from Classification Society ClassNK for Ammonia Fuel Supply System (AFSS)

Apr 11, 2024 17:50 JST

|

DOCOMO, NTT, NEC and Fujitsu Develop Top-level Sub-terahertz 6G Device Capable of Ultra-high-speed 100 Gbps Transmission

Apr 11, 2024 15:10 JST

|

Mitsubishi Corporation Announces Completion of Capital Raise by Nexamp

Apr 11, 2024 13:07 JST

|

Mitsubishi Shipbuilding Receives Order for Ammonia Fuel Supply System for Ammonia-Powered Marine Engine

Apr 10, 2024 16:55 JST

|

Transgene and NEC Present First Clinical Benefits of Neoantigen Cancer Vaccine, TG4050, in Head & Neck Cancer at AACR 2024

Apr 10, 2024 13:36 JST

|

More Latest Release >>

|