TOKYO, Aug 22, 2025 - (JCN Newswire) - TANAKA MIRAI Lab., part of TANAKA PRECIOUS METAL GROUP Co., Ltd. (head office: Chuo-ku, Tokyo; Group CEO: Koichiro Tanaka), has developed an experimental unit for space molecular crystallization using Au nanostructure formation technology (patent pending). On April 21, 2025 (local time), the experimental unit was installed in the SpaceX CRS-32, an unmanned commercial resupply spacecraft to the International Space Station (ISS) launched from the Kennedy Space Center in the U.S.

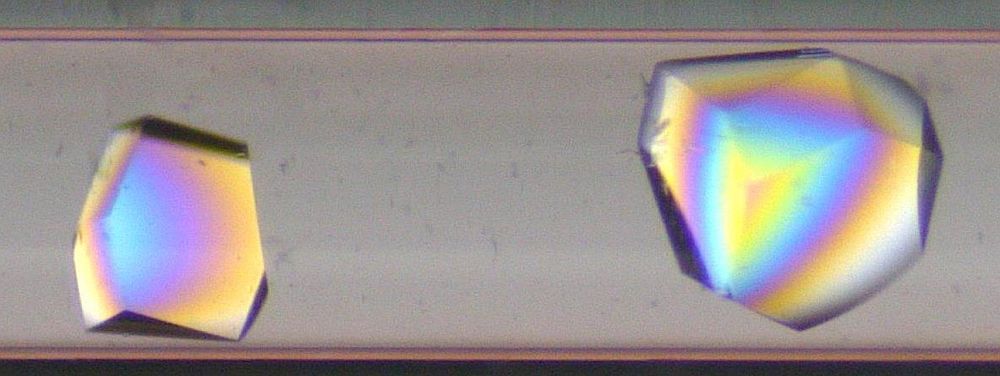

Protein crystals formed within the experimental unit installed in the space station

Protein crystals formed within the experimental unit installed in the space station

(magnified using a polarizing microscope)

After installation in the ISS's Columbus science laboratory and one month of observation and experimentation, it safely returned to Earth, where it was confirmed that the experiments involving protein crystallization in space were successful.

Significance of the Experiment

Protein crystallization experiments conducted in space are valuable for detailed structural analysis of protein molecules, as they can be carried out in a microgravity environment, eliminating the effects of gravity. Such experiments are expected to make significant contributions to understanding biological functions and advancing drug discovery. However, the success rate of producing crystals remains low, and the high costs along with the limited number of experiments that can be performed continue to pose challenges for space-based research. The experimental unit for space molecular crystallization, developed by TANAKA MIRAI Lab. and utilizing Au nanostructure formation technology, is expected to enable more cost-effective space experiments with superior outcomes. By leveraging protein crystallization technology based on the plasmon resonance (*1) of gold (Au), it can significantly improve the crystal generation rate. This advancement is anticipated to contribute to the elucidation of biological functions and to research in drug discovery.

Superiority of “Experimental Unit for Space Molecular Crystallization Using Au Nanostructure Formation Technology”

Protein molecules are easily absorbed onto the surface of Au nanoparticles, and plasmon resonance occurs between Au nanoparticles at wavelengths in the visible light range, promoting protein crystallization.

TANAKA MIRAI Lab. has discovered that the condensation of light energy between Au nanoparticles further promotes the generation of protein crystal nuclei. In addition, in the microgravity environment of space, crystals of higher quality and larger size than those on the ground are expected to be generated because they are not affected by convection and sedimentation due to gravity.

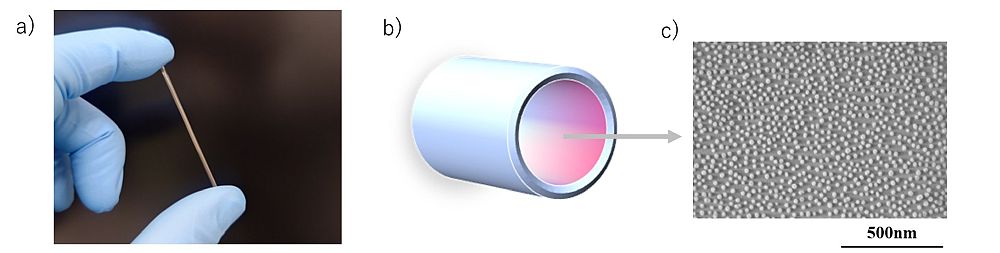

In combination with Au nanostructure formation technology, TANAKA MIRAI Lab. has developed a capillary (cylindrical glass device) (Figure 1) with high crystal generation capabilities (patent pending) for use in the counter-diffusion(*2) method.

On the inner wall of the capillary with an inner diameter of 0.5 mm and a length of 5 cm, nano-level particles of Au (average diameter: 20 nm) are aligned at nano-level intervals (average distance between surfaces: 40 nm) that facilitate the generation of plasmon resonance near the surface of Au particles.

In addition to conducting experiments in space, which is unaffected by gravity, the use of this unit is expected to dramatically improve the rate of obtaining protein crystals, which had been considered challenging. As a result, it is believed that this unit will contribute to the elucidation of biological functions and the development of drug discovery research.

Figure 1: a) Photo of capillary b) Schematic diagram of capillary c) Electron microscope image of inner wall

Figure 1: a) Photo of capillary b) Schematic diagram of capillary c) Electron microscope image of inner wall

Overview of the Experiment

Kirara, a space experiment service supplied by Japan Manned Space Systems Corporation (https://www.jamss.co.jp/en/space_utilization/kirara/), a space experiment consulting company, was used to install the experimental unit for space molecular crystallization using Au nanostructure formation technology in the SpaceX CRS-32 unmanned commercial resupply spacecraft.

Specifically, capillaries were filled with protein solution and sealed in a tube (bag) which was stored within the Kirara device (a thermostatic chamber). This unit was then placed in the rocket and launched into space.

Timeline of experiments involving protein crystallization in space

* All times are U.S. local times

- April 7: Specimens sent from Japan to the U.S.

- April 13: Specimens arrive in Kennedy Space Center in Florida (U.S.)

- April 19: Specimens are loaded into Kirara device and placed in rocket

- April 21: Kirara device is launched into space on a Space-X Falcon 9 rocket (CRS-32)

- April 22: Kirara device arrives at International Space Station (the ISS)

- April 23: Kirara device is installed in the ISS Columbus science laboratory

- May 21: Kirara device is removed from the ISS Columbus science laboratory

- May 25: CRS-32 with Kirara device returns to Earth

Results of the Experiment

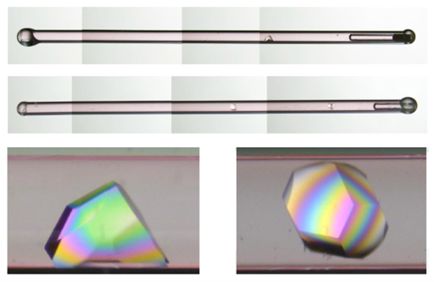

The experimental unit for space molecular crystallization using Au nanostructure formation technology was used to successfully crystallize proteins in space (Figure 2).

Figure 2: Top) Protein crystals formed in capillaries containing crystallization solution with NaCl concentration of 750 mM

Bottom) Magnified view of protein crystals taken using polarizing microscope

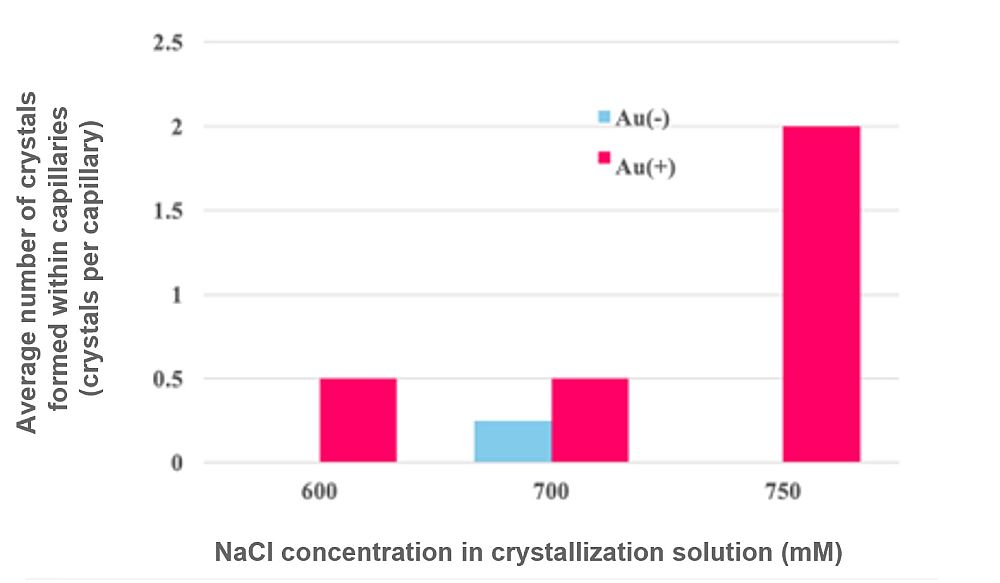

The graph below (Figure 3) shows the final results of the protein crystallization experiment performed on the ISS(*3). The horizontal axis represents the concentration of the NaCl in the crystallization solution (mM). The vertical axis represents the average number of crystals that formed in the capillary (crystals per capillary).

The blue bars (Au(-)) show the results for capillaries without Au nanostructures, while the red bars (Au(+)) show the results for capillaries with Au nanostructures.

As the graph shows, the number of crystals that formed was higher for capillaries with Au nanostructures (the red bars on the graph).

Experimental conditions

● Capillary conditions: Capillaries with an inner diameter of 0.5 mm were used, and a structure of nano-level particles of Au with a diameter of 20 nm was formed on the inner walls of the capillaries (in the same way as for experiments performed on Earth in advance).

● Solution conditions: Lysozyme refined for the space experiment was used as a solvent for protein (25 mg/L). For the crystallization solution, three NaCl concentrations were prepared: 650 mM, 700 mM, and 750 mM. These solutions included an acetic acid buffer (pH 4.5) with a concentration of 50 mM and PEG (4K) 20%.

● Crystallization experiment: The counter-diffusion method was used, and the units were kept stationary at a temperature of 20°C in a weightless environment for 34 days, during which the crystallization process was observed.

Comments from Researchers Responsible for the Experiment

Takayuki Ishibashi

Chief Researcher, TANAKA MIRAI Lab.

Ever since TANAKA MIRAI Lab. was first launched, we've envisioned precious metals as being used in extreme environments. Many projects never get beyond their planning phases, so I'm ecstatic that our first success was with an experiment in space, and that we've been able to exhibit the actual articles used in the experiment in our concept room here within the company. Seeing the proteins that crystallized in space here on Earth, with my own eyes, I felt again the potential for future crystal applications as we work toward the year 2085. We were able to achieve this success thanks to the combined efforts of many people, and I'd like to express my gratitude again to all those involved, both inside and outside the company.

Masahiro Ito

Chief Researcher, TANAKA MIRAI Lab.

This space project was a tremendously meaningful one for us, as it represented a great step forward. As a company that deals with precious metals, there have long been expectations for our participation in the space industry, but this was our first time really taking on a challenge in this sector. The project started out of a desire not just to think about things at the conceptual level but to test them out in space. I believe it reflects the spirit of TANAKA MIRAI Lab. — harnessing curiosity to drive our pursuit of creating rare and exceptional value for the future.

Figure 4: Left) The experimental unit used in the ISS Right) Replica of the Kirara device

(On exhibit in the DOCK2085 concept room at the head office)

(*1) Plasmon resonance: A phenomenon in which light of a specific wavelength is absorbed on an Au surface that has been nanoparticulated. It is further enhanced when Au nanoparticles are close together at nano-level spacing.

(*2) Counter-diffusion method: One of the protein crystallization methods, in which crystals are obtained by bidirectional diffusion of the protein solution inside the capillary and the crystallization solution outside. During this process, a concentration gradient is generated inside the capillary, which makes it possible to simultaneously search for a wide range of crystallization conditions. In addition, since the protein is not concentrated during crystallization, crystal growth proceeds gently.

(*3) While more crystals were generated in the unit with the Au nanostructures, the experiments were performed under a limited number of experimental conditions, so this cannot be concluded to represent a significant difference. Furthermore, the overall number of crystals that were generated was low in comparison to prior experiments performed on Earth. This is believed to be due to a large number of days passing between when the capillaries were filled with solution and when the crystallization began.

About TANAKA MIRAI Lab.

TANAKA has been advancing a transformation of its overall business toward the year 2085, the 200th anniversary of its founding, with the aim of “creating a future that no one has ever seen before.” As part of this initiative, TANAKA launched TANAKA MIRAI Lab., an organization to lead the creation of new paradigms for a better future—from emergence to realization.

TANAKA MIRAI Lab.’s mission is to envision an unseen future and realize various possibilities by conducting research derived from “kisho (precious and rare) value.”

About TANAKA

Since its foundation in 1885, TANAKA has built a portfolio of products to support a diversified range of business uses focused on precious metals. TANAKA is a leader in Japan regarding the volume of precious metals it handles. Over many years, TANAKA has manufactured and sold precious metal products for industry and provided precious metals in such forms as jewelry and assets. As precious metals specialists, all Group companies in Japan and worldwide collaborate on manufacturing, sales, and technology development to offer a full range of products and services. With 5,591 employees, the group's consolidated net sales for the fiscal year ended December 2024 were 846.9 billion yen.

TANAKA Industrial Precious Metal Materials Portal

https://tanaka-preciousmetals.com

Press inquiries

TANAKA PRECIOUS METAL GROUP Co., Ltd.

https://tanaka-preciousmetals.com/en/inquiries-for-media/

Press release: https://www.acnnewswire.com/docs/files/2025821.pdf