|

Showa Denko Develops WelQuick(TM) to Bond Dissimilar Materials Quickly

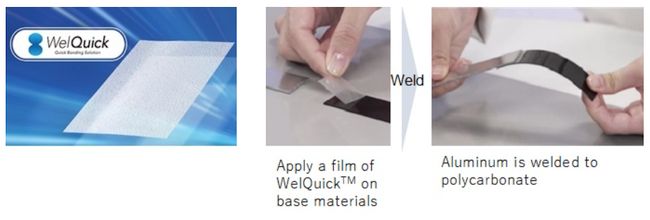

TOKYO, Jun 28, 2021 - (JCN Newswire) - Showa Denko K.K. (SDK; TSE:4004) has developed "WelQuick(TM)," a film-type binding material to bond dissimilar materials together, such as bonding between resins and metals, with excellent quickness and strength. SDK has already started to provide potential customers with samples of WelQuick.

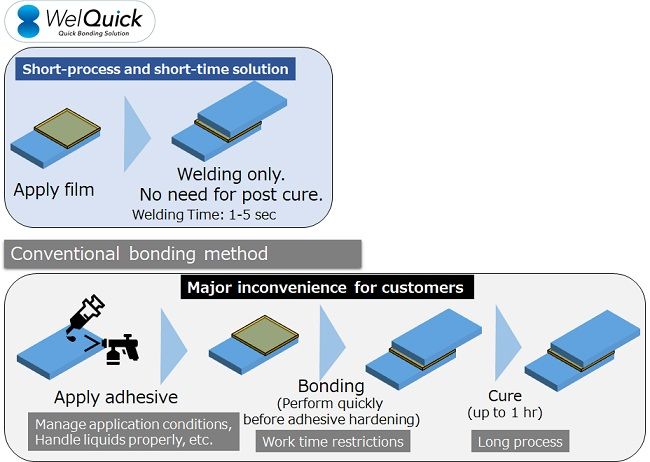

| | Comparison of WelQuick(TM) bonding method and conventional bonding method |

| |

In recent years, manufacturing industry's requirements for materials such as lightness, heat-resistance and strength have been advanced so much that almost no single material can meet such sophisticated needs. Therefore, there has been a progress in introduction of composite structure into components, in which dissimilar materials such as resins and metals are bound together. This movement is called "multi-materialization." There are many methods to bond dissimilar materials, such as bonding with liquid adhesives or hot-melt adhesives, and mechanical fastening with bolts. Though manufacturers demand simple, easy and timesaving bonding process while securing enough adhesive strength. However, simultaneous achievement of simplicity and adhesiveness has been difficult.

WelQuick, which has been developed by SDK, is a film-type adhesive component, and eliminates the process to apply liquid components which was necessary process for reactive adhesives. Therefore, WelQuick is easy to handle, and shortens bonding time to a few seconds by utilizing the phase change[1] between solid and liquid, while bonding with conventional adhesives takes dozens of minutes.

WelQuick can bond resins and metals. The former includes polycarbonate, polyethylene terephthalate and nylon, while the latter includes aluminum, iron and copper. SDK has confirmed that WelQuick can achieve shear adhesive strength[2] of more than 10MPa[3] with more than 40 combinations of base materials. Moreover, our customers can choose welding method suitable for their needs from wide variety of welding methods including ultrasonic welding which realizes high-speed welding, electromagnetic induction welding which is suitable for metals, and heat welding which is suitable for various materials. Furthermore, films of WelQuick can be stored at room temperature for long periods. WelQuick does not produce volatile organic compounds (VOCs) when welded. Thus WelQuick lowers the burden on the environment.

On the basis of these strong points, WelQuick can contribute to customers' cost reduction and reduction of CO2 emission through improvement in efficiency of production processes.

The Showa Denko Group has wide-ranging technologies and materials concerning inorganics, organics and aluminum. By fusing these technologies into one, the Group will provide various business fields, where multi-materialization is in progress, with new solutions, and aim to maximize the value of Customers' Experience.

For further detail of WelQuick technology, please refer to the following URL.

https://www.sdk.co.jp/innovation/english/points/welquick.html

For data on the properties of WelQuick, please refer to the following URL.

https://www.sdk.co.jp/innovation/english/download/welquick/leaflet/input.html

Comparison of WelQuick bonding method and conventional bonding method

https://www.sdk.co.jp/assets/images/english/news/2021/20210628_3_e.jpg

[1] Phase change: Changes in the state of material (gas, liquid and solid) caused by changes in temperature and pressure. WelQuick(TM) technology utilizes liquefaction of solid and solidification of liquid.

[2] Shear adhesive strength: Adhesive strength that acts on the surfaces of adhered materials parallel to adhered surfaces when the base materials are pulled to opposite directions to slide laterally.

[3] MPa (Mega Pascal): The SI unit of pressure. If the two sample materials show shear adhesive strength of 10MPa, one square centimeter of adhered surface requires forces of about 100kg to be peeled off.

About Showa Denko K.K.

Showa Denko K.K. (SDK; TSE:4004, ADR:SHWDY) is a major manufacturer of chemical products serving from heavy industry to computers and electronics. The Petrochemicals Sector provides cracker products such as ethylene and propylene, the Chemicals Sector provides industrial, high-performance and high-purity gases and chemicals for semicon and other industries, the Inorganics Sector provides ceramic products, such as alumina, abrasives, refractory/graphite electrodes and fine carbon products. The Aluminum Sector provides aluminum materials and high-value-added fabricated aluminum, the Electronics Sector provides HD media, compound semiconductors such as ultra high bright LEDs, and rare earth magnetic alloys, and the Advanced Battery Materials Department (ABM) provides lithium-ion battery components. For more information, please visit www.sdk.co.jp/english/.

Media contact:

Showa Denko K.K., CSR & Corporate Communication Office, Tel: +81-3-5470-3235

Source: Showa Denko K.K.

Sectors: Chemicals, Spec.Chem, Materials & Nanotech

Copyright ©2026 JCN Newswire. All rights reserved. A division of Japan Corporate News Network. |

Latest Release

NTT DOCOMO Develops a Solution to Streamline DOOH Advertiser Review Operations

Jan 27, 2026 10:25 JST

|

Fujitsu launches new platform enabling autonomous operation of generative AI optimized for in-house applications in a dedicated environment

Jan 26, 2026 13:30 JST

|

Mitsubishi Heavy Industries and Mitsubishi Electric Invest in Japan LEO Shachu, a Space Venture Established by Mitsui & Co.

Jan 26, 2026 13:24 JST

|

CaoCao Inc. Ushers in China's Fully Purpose-Built Robotaxi Era, Aims to Deploy 100,000 Robotaxis by 2030

Jan 26, 2026 11:51 JST

|

FDA Accepts LEQEMBI(R) IQLIK(TM) (lecanemab-irmb) Supplemental Biologics License Application as a Subcutaneous Starting Dose for the Treatment of Early Alzheimer's Disease under Priority Review

Jan 26, 2026 11:37 JST

|

Fujitsu to support Mizuho Financial Group's human capital disclosure with a non-financial information collection and disclosure support service

Jan 26, 2026 10:45 JST

|

TOYOTA GAZOO Racing Announces GR Yaris Sebastien Ogier 9x World Champion Edition

Jan 23, 2026 19:26 JST

|

NEC Develops New 5G Base Station Radio Unit for Enhanced Communication Throughput, Compactness, and Energy Efficiency

Jan 23, 2026 15:00 JST

|

GlobalLogic and Elektrobit Strengthen Partnership to Accelerate Next-Generation Software-Defined Vehicles

Jan 23, 2026 14:12 JST

|

Fujitsu and Mizuho Bank partner to develop new order and payment processing service for SMEs

Jan 22, 2026 11:30 JST

|

TANAKA PRECIOUS METAL TECHNOLOGIES to Exhibit Advanced Precious Metal Materials for Medical Device Components at MD&M West 2026

Jan 21, 2026 22:00 JST

|

Honda to Discontinue Production of Fuel Cell Systems at Fuel Cell System Manufacturing LLC in the U.S.

Jan 21, 2026 17:44 JST

|

Notice regarding the dissolution of the joint venture in the home elevator business

Jan 21, 2026 17:04 JST

|

Eisai Listed as a Global 100 Most Sustainable Corporation for the Tenth Time

Jan 21, 2026 16:44 JST

|

MHI and ITB Deepen Research Collaboration on Ammonia-Based Clean Power in Indonesia

Jan 21, 2026 16:37 JST

|

Asian Financial Forum opens next Monday with a fresh perspective and new tagline, Finance Empowering Business

Jan 21, 2026 14:30 JST

|

MHI-TC Delivers Self-Propelled Mobile Seaport Passenger Boarding Bridge to Yokohama City, Entering Service on January 13th

Jan 21, 2026 11:02 JST

|

From Computing Chips to Physical AI: Nobel Laureate Hassabis' Trillion-Dollar Paradigm Forecast and 51WORLD's (6651.HK) Industry Breakthrough

Jan 21, 2026 10:00 JST

|

Overview of Speeches Delivered at Launch Event for New Partnership between Honda and the Aston Martin Aramco Formula One(R) Team for 2026 Season

Jan 20, 2026 14:19 JST

|

Mitsubishi Motors Marks Record Sales in Vietnam for the Second Consecutive Year in 2025

Jan 20, 2026 12:35 JST

|

More Latest Release >>

|