|

MHIENG Receives Highest Award among 2021 Outstanding Energy-Efficient and Decarbonizing Industrial Machinery & Systems

- Japan Machinery Federation's highest "METI Minister's Award" recognizes MHIENG's CO2 capture system as machinery that contributes to decarbonization

- Awards presented to companies for development and commercialization of outstanding energy-efficient, decarbonizing industrial machinery and systems

TOKYO, Mar 01, 2022 - (JCN Newswire) - Mitsubishi Heavy Industries Engineering, Ltd. (MHIENG), a group company of Mitsubishi Heavy Industries, Ltd. (MHI), has been named recipient of the METI (Ministry of Economy, Trade and Industry) Minister's Award, the highest among the 2021 Outstanding Energy-Efficient and Decarbonizing Industrial Machinery & Systems Awards bestowed by The Japan Machinery Federation (JMF). MHIENG received the award for "KS-21,"(1) an innovative new solvent jointly developed with Kansai Electric Power Co., Inc. (KEPCO), and its "Advanced KM CDR Process," a cutting-edge carbon capture process adopting the KS-21.

| | Awards Ceremony |

| | Awards Ceremony |

| | Carbon capture process |

The JMF awards are given to promote the adoption and further development of outstanding energy-efficient industrial machinery and systems as well as effectively contribution for decarbonization. The development and widespread adoption of such machinery and systems by the industrial sector are considered indispensable globally toward achieving carbon neutrality by 2050.

Commercialization of the KS-21 solvent was completed following demonstration testing in 2021 at the Technology Centre Mongstad in Norway, one of the world's largest carbon capture demonstration facilities. MHIENG has also agreed a long-term contract with Drax Group, a renewable energy company based in the United Kingdom, to use the proprietary KS-21 solvent at its power station in North Yorkshire. The project aims to capture and store at least 8 million tonnes of CO2 a year by 2030 - making it the world's largest carbon capture in power project.(2)

MHI Group today is undertaking strategic initiatives to strengthen its business in products supporting the energy transition, and development of CO2 ecosystems is a core part of those efforts. Carbon capture, utilization and storage (CCUS) is garnering attention as an effective means for realizing a carbon neutral society. As of January 2022, MHIENG accounts for the world's highest share with respect to volume of carbon captured from flue gas at commercial plants. By promoting widespread adoption of its high-performance carbon capture technologies globally, the company aims to contribute to reducing greenhouse gas emissions on a global scale. Going forward, MHIENG will continue its efforts to further develop proprietary technologies that will contribute to protecting the earth's environment.

(1) For further information on the KS-21's demonstration testing results and major characteristics, refer to the following press release: https://www.mhi.com/news/211019.html

(2) For information on the carbon capture project jointly underway by MHIENG and Drax, refer to the following press releases:

https://www.mhi.com/news/200624.html

https://www.mhi.com/news/210610.html

The Award-Winning Products

1. Overview

To address global warming, today countries everywhere are vigorously called on to promote large-scale CCS and CCUS projects within constrained budgets.

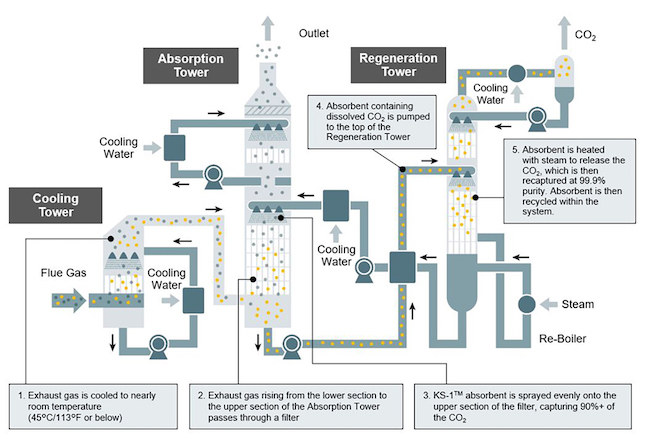

In response to that call, MHIENG developed technology enabling chemical absorption of the CO2 content of flue gas emissions. The original technology consisted of "KS-1" - a solvent whose high reliability has been confirmed by a track record of deliveries to 13 commercial plants worldwide - and the "KM CDR Process" for carbon capture. The award-winning, cost-saving "Advanced KM CDR Process" supersedes that earlier configuration and incorporates "KS-21" solvent.

2. Major characteristics (compared to KS-1 and generally used amine-based solvent MEA)

a. KS-21 solvent offers lower volatility and higher stability against degradation. Its contributions in terms of reducing absorption reaction heat and capture energy translate to potential economic benefits with respect to lower operating costs for the customer, etc.

b. A low level of amine emissions results in reduced solvent consumption and lighter impact on the environment. (Environmental impact assessment by a third-party institution has yielded highly reliable emissions measurements.)

c. The new system can accommodate carbon capture from a variety of flue gas sources. It supports customers in industrial and infrastructure areas including not only conventional power generation and chemical plants, but also biomass and LNG liquefaction plants, steel and cement factories, waste incineration facilities, etc., from project formulation stages including basic design, pilot demonstration, licensing, etc.

3. Carbon capture information

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world's leading industrial groups, spanning energy, logistics & infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.

Source: Mitsubishi Heavy Industries, Ltd.

Sectors: Manufacturing

Copyright ©2025 JCN Newswire. All rights reserved. A division of Japan Corporate News Network. |

Latest Release

DENSO Acquires Axia Vegetable Seeds to Realize Sustainable Agriculture

Jul 04, 2025 16:20 JST

|

MHIET Launches 450kW Gas Cogeneration System Capable of Hydrogen Co-Firing

Jul 04, 2025 15:13 JST

|

Yachiyo Engineering and NEC launch adaptation finance study in Indonesia to calculate the adaptation value of disaster prevention measures

Jul 04, 2025 13:25 JST

|

Fujitsu to implement store monitoring solution for METRO Inc. in Canada, enhancing operational efficiency and policy compliance

Jul 04, 2025 13:19 JST

|

Fujitsu to develop ETF trading platform based on TSE's CONNEQTOR and provide it to Australian Securities Exchange

Jul 03, 2025 11:14 JST

|

Mitsubishi Motors Launches the All-New Grandis for the European Market

Jul 02, 2025 12:10 JST

|

Valuufy partners with Mainichi Future Creation Lab, Supporting New Approaches to Business Sustainability

Jul 02, 2025 12:00 JST

|

Fujitsu launches solution to enhance customers' global supply chain resilience

Jul 02, 2025 11:32 JST

|

MHI Receives Order to Supply Four Circulating Water Pumps for Units 5 and 6 of Sanmen Nuclear Power Plant in China Under Collaboration with Dongfang Electric Machinery

Jul 02, 2025 11:30 JST

|

Multi-purpose Arena in Odaiba Aomi Area TOYOTA ARENA TOKYO Construction Completed

Jul 01, 2025 22:56 JST

|

1Finity, a Fujitsu company, commences operations and reveals brand identity

Jul 01, 2025 22:53 JST

|

MHI Thermal Systems Begins Field Test of Jointly Developed "Surplus Renewable Energy Absorption and Release System"

Jul 01, 2025 22:40 JST

|

Japan's Telecommunications Carriers Strengthen Disaster Response Through Collaborative Information Sharing

Jul 01, 2025 22:30 JST

|

JCB and Mandai Wildlife Group Deepen Partnership with exclusive discounts for JCB cardmembers

Jul 01, 2025 16:00 JST

|

Fujitsu provides Japan's first AI-powered cloud-based library search service

Jul 01, 2025 11:30 JST

|

JCB Brings Apple Pay to Cardmembers in Vietnam

Jul 01, 2025 11:15 JST

|

First Shipment of LNG from the LNG Canada Project

Jul 01, 2025 11:00 JST

|

Approval in Principle (AiP) for World's First LCO2 / Methanol Carrier

Jun 30, 2025 20:30 JST

|

Acropolis Rally Greece: Day 4 Sunday success and second overall for TOYOTA GAZOO Racing's Ogier

Jun 30, 2025 20:15 JST

|

Mitsubishi Fuso-Hino Merger: 4 Firms Collaborate for the Future of Commercial Vehicles

Jun 30, 2025 20:10 JST

|

More Latest Release >>

|