|

Fujitsu Begins Sales of Digital Solution "COLMINA" to Create Connected Services in the Manufacturing Industry

TOKYO, May 09, 2017 - (JCN Newswire) - Fujitsu today announced that it has systematized its support services for increasing the competitiveness of manufacturers in Japan, and this is to be available on a platform known as Fujitsu Manufacturing Industry Solution COLMINA, a place for connecting all kinds of digital manufacturing information, from design to production and maintenance.

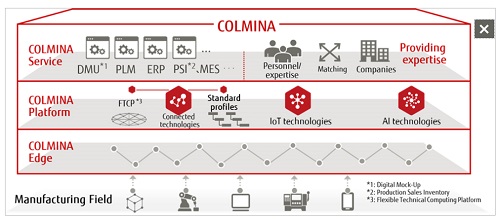

| | Figure 1: Structural diagram for the manufacturing digital solution COLMINA |

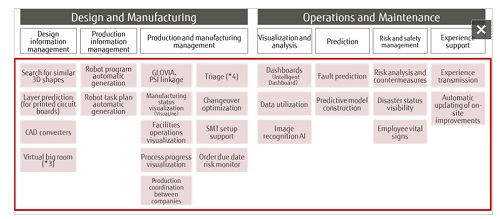

| | Figure 2: COLMINA service at a glance |

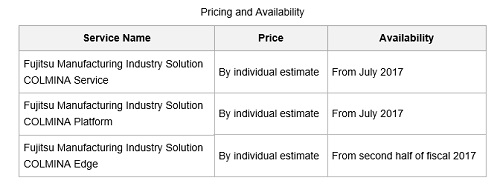

| | Pricing and Availability |

COLMINA links data on the location of people and products, on factory equipment, and all systems and know-how throughout the manufacturing process, as well as data among companies in the supply chain.

As the services underlying this solution, there is the Fujitsu Manufacturing Industry Solution COLMINA Service, a suite of a variety of operational services for manufacturing, the Fujitsu Manufacturing Industry Solution COLMINA Edge, which collects and processes sensor data, such as on equipment operations, the vital signs of people, and the location of products, and the Fujitsu Manufacturing Industry Solution COLMINA Platform, which brings together the COLMINA Service and the COLMINA Edge. Sales will begin in Japan in phases starting in July 2017.

Going forward, Fujitsu will offer standard interfaces between the COLMINA Platform and other companies' solutions and platforms. Because this enables data on everything from design to production to be linked throughout the entire supply chain, it will facilitate the digital transformation of all manufacturing work.

It also helps manufacturing companies share their skilled workers' knowledge relating to design, production, and maintenance, as well as identify talented workers and match them to appropriate positions, and promote collaboration and co-creation with other companies.

COLMINA will be exhibited at Fujitsu Forum 2017, to be held May 18-19 at Tokyo International Forum.

Background

Amid a rapidly changing market environment, with a diversification of customer needs, many companies are using digital technologies, such as IoT and AI, to work on digital transformation initiatives in order to generate innovation and strengthen their competitiveness.

In manufacturing, with the advance of the fourth industrial revolution, Japan's Ministry of Economy, Trade and Industry (METI) and Germany's Ministry for Economic Affairs and Energy in March 2017 signed a joint statement, the "Hannover Declaration," on cooperation in IoT / Industrie 4.0 initiatives. METI also announced its "Connected Industries(2)" policy concept to create its vision of a "Society 5.0(1)" super-smart society.

Over many years, Fujitsu has been raising the efficiency of its operations through "virtual manufacturing," which makes use of its manufacturing experience and simulations. Incorporating this manufacturing expertise, COLMINA seeks to be a manufacturing platform that will also bring about a Society 5.0 super-smart society.

About COLMINA

In addition to the solutions and services for the manufacturing industry that Fujitsu has been offering for over 30 years, COLMINA is a place where Fujitsu delivers a manufacturing solution that links together all kinds of information relating to manufacturing, from design to production and maintenance.

http://www.acnnewswire.com/topimg/Low_FujitsuCOLMINAFig1.jpg

Figure 1: Structural diagram for the manufacturing digital solution COLMINA

1. COLMINA Service

COLMINA Service encompasses a variety of operational services for everything from design to production and maintenance.

Under the COLMINA Service umbrella, Fujitsu plans to provide 150 different services over time, including the existing services it is providing to the manufacturing industry. In the first batch, the 25 services below will be rolled out in phases in Japan from July 2017.

http://www.acnnewswire.com/topimg/Low_FujitsuCOLMINAFig2.jpg

Figure 2: COLMINA service at a glance

2. COLMINA Platform

COLMINA Platform is a platform that connects all kinds of companies' manufacturing front lines, people, and things through data, and generates new services for the manufacturing industry.

Big data technologies that collect and analyze a variety of equipment data and standardized data formats defined through the activities of such organizations as the Robot Revolution Initiative and the Industrial Value Chain Initiative will be incorporated for use through APIs(5). In the future, Fujitsu also plans to provide APIs for Fujitsu Zinrai AI technologies through this platform.

3. COLMINA Edge

COLMINA Edge is a feature that collects a variety of equipment data, converts it into an optimal data format, and links it with data from each type of service on COLMINA. To link with machinery, a system is provided to link with edge platforms provided by other companies.

Future Plans

With COLMINA, Fujitsu is also planning to offer services such as consulting services aimed at factory automation, and personnel services including matching people and companies. In addition, Fujitsu will also provide a development environment so that start-ups and other companies can develop services on COLMINA. Through these measures, Fujitsu aims to not stop at providing solutions and services, but also to provide a place for innovation in COLMINA, where a variety of expertise is available.

Endorsement

Comment from Tomoaki Kubo, Robot Revolution Initiative

Industry in Japan aims to provide new added value through a variety of connections with Connected Industries. At the Robot Revolution Initiative, we support activities by partner companies to make Connected Industries a reality.

Pricing and Availability

http://www.acnnewswire.com/topimg/Low_FujitsuCOLMINAPricing.jpg

Sales Target

Revenue of 200.0 billion yen in COLMINA-related business by fiscal 2020.

(1) Society 5.0

A series of initiatives promoted by the Japanese government aimed at sharing the vision of and bringing about a future "super smart society," in which cyberspace and physical space (the real world) are fused to a high degree.

(2) Connected Industries

A policy concept aimed at building a new industrial society using Japan's technological and manufacturing capabilities together with connections from digital technology, with a fundamental conception of an industrial society that can create new value through a variety of connections.

(3) Virtual Big Room

Offers a system that manages experience related to product development, including design information, analysis results, and the content of discussions with manufacturing departments, and in which necessary information can be called up at any time when using a computer. Fujitsu also plans to add voice coordination going forward.

(4) Triage

Rescheduling production plans based on a real-time understanding of current status on the ground when temporary stoppages occur. Fujitsu offers a system that displays response priorities in order to resume production without delay.

(5) API

Application Programming Interface. Code establishing methods and file formats to enable outside programs to call on the functions and data handled by a computer program (software).

Contact:Fujitsu Limited

Public and Investor Relations

Tel: +81-3-3215-5259

URL: www.fujitsu.com/global/news/contacts/

Source: Fujitsu Ltd

Sectors: Enterprise IT

Copyright ©2026 JCN Newswire. All rights reserved. A division of Japan Corporate News Network. |

Latest Release

Lockheed Martin and Fujitsu Formalize Industrial Collaboration for Japan Defense

Feb 12, 2026 19:59 JST

|

Meiji and Fujitsu launch world's first rRAFU(TM) pilot to assess future malnutrition and frailty risk

Feb 12, 2026 16:09 JST

|

Fujitsu Group starts manufacturing sovereign AI servers in Japan to enhance digital sovereignty

Feb 12, 2026 12:13 JST

|

Premiere of Three-Row Highlander BEV in North America

Feb 11, 2026 14:25 JST

|

Honda Works Partner Aston Martin Aramco Formula One(TM) Team Unveils Livery of "AMR26" F1(TM) Machine Equipped with Honda Power Unit Ahead of the 2026 Race Season

Feb 10, 2026 18:25 JST

|

Honda to Make Organizational Changes to Further Enhance Competitiveness its Motorcycle, Automobile and Power Products Business

Feb 10, 2026 17:53 JST

|

KS Energy and Hitachi Collaborate on Extra-High Voltage Battery Energy Storage System

Feb 10, 2026 14:15 JST

|

Biologics License Application for Subcutaneous Formulation of "LEQEMBI(R)" (lecanemab) for the Treatment of Early Alzheimer's Disease Designated for Priority Review in China

Feb 10, 2026 13:34 JST

|

NEC Exhibits at MWC Barcelona 2026, the World's Largest Mobile-Related Exhibition

Feb 09, 2026 21:18 JST

|

CITIC Telecom CPC Wins Two Awards, Celebrating 'Innovation Never Stops' for 25 Years, recognizing Cybersecurity & Innovation Excellence

Feb 09, 2026 14:28 JST

|

JCB Announces Collaboration with Resorts World Sentosa in Singapore

Feb 09, 2026 14:00 JST

|

Anime Tokyo Station: "That Time I Got Reincarnated as a Slime" Special Exhibition, February 21 to May 24, 2026

Feb 09, 2026 11:00 JST

|

Mitsubishi Motors Launches the All-New Versa Van in the Philippine Market

Feb 06, 2026 13:34 JST

|

Establishment of the World's First*1 Global Supply Chain to Introduce the Use of Renewable Plastics in Sony's High-Performance Products

Feb 06, 2026 11:50 JST

|

Eisai and Henlius Enter into Exclusive Commercial License Agreement for Anti-PD-1 Antibody Serplulimab in Japan

Feb 06, 2026 11:31 JST

|

Fujitsu Japan and JMDC announce collaboration to build sustainable healthcare system in Japan through enhanced medical data utilization

Feb 06, 2026 11:14 JST

|

Genesys and Fujitsu Transform AEON Financial Service's Contact Center Operations with Genesys Cloud Delivers Customers an Improved Self-Service Experience Resulting in Higher Completion and Reduced Wait Times

Feb 06, 2026 10:44 JST

|

TANAKA PRECIOUS METAL TECHNOLOGIES establishes total solutions system for contract manufacturing of various test kits including in vitro diagnostics

Feb 05, 2026 22:00 JST

|

Everest Medicines Announces Exclusive License Agreement with Micot to Commercialize MT1013

Feb 05, 2026 11:55 JST

|

Hitachi significantly expands exhibits at the "Hitachi Building Solutions Lab", a research facility for collaborative creation with customers

Feb 05, 2026 11:48 JST

|

More Latest Release >>

|