|

Fujitsu Laboratories Develops Pure Carbon-Nanotube Sheets with World's Top Heat-Dissipation Performance

KAWASAKI, Japan, Nov 30, 2017 - (JCN Newswire) - Fujitsu Laboratories Ltd. today announced the successful development of a high-thermal-conductive carbon-nanotube sheet with the world's top heat dissipation performance. The sheet is composed of pure(1) carbon nanotubes, oriented perpendicularly, resulting in exceptional thermal conductivity and heat resistance.

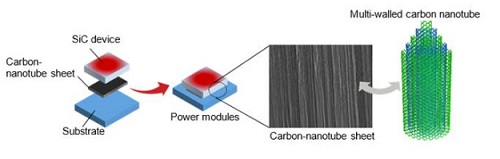

| | Figure 1: Schematic drawing of carbon nanotubes as heat-dissipation sheets. |

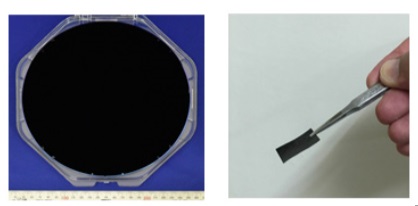

| | Figure 2: Image of multi-walled carbon nanotubes synthesized all over the surface of a 200-mm silicon substrate (left) and carbon-nanotube sheet (right). |

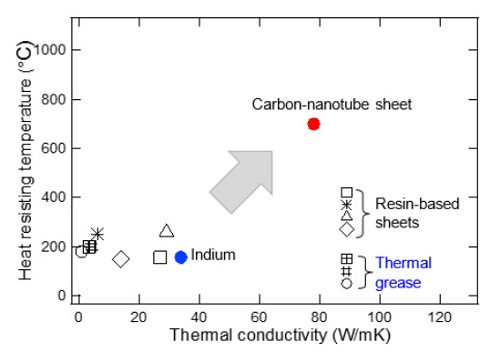

| | Figure 3: Graph of characteristics. For comparison, actual measured thermal conductivity of conventional thermal interface materials such as indium, resin-based sheets and thermal grease are shown. |

The rapidly growing prevalence of electric vehicles has created demand for onboard power modules to control high-voltage electric power with low power demands of their own and high breakdown voltage, while at the same time needing to maintain reliability despite the high-temperature operations that come with compact modules. Silicon carbide (SiC), which has low power consumption and a high breakdown voltage, is being used as an alternative for silicon, but in order to operate reliably at temperatures of 200degC or higher, heat needs to be removed efficiently from SiC devices.

Fujitsu Laboratories has now developed a process for manufacturing carbon nanotubes, a material known for its high thermal conductivity in a cylindrical structure, and in which the combination of process temperature and pressure is precisely controlled to grow dense, uniform arrays of perpendicularly oriented carbon nanotubes. In order to be used for removing heat from SiC power modules, Fujitsu Laboratories has also developed a sheet-forming technology in which oriented-growth carbon nanotubes are subjected to heat treatment at temperatures above 2000degC, creating sheets that are easy to transport. Heat-dissipation sheets made using these technologies have about three times the heat-dissipation performance of existing materials made using indium, and have been found to have the world's best heat-dissipation performance among carbon-nanotube sheets.

Fujitsu Laboratories plans for this technology to be used in automotive heat-dissipation materials from fiscal 2020, and is considering to expand business into new areas, such as in applications for next-generation high-performance computing and telecommunications equipment.

Details of this technology are being presented at the 2017 Workshop on Innovative Nanoscale Devices and Systems (WINS2017) in Hawaii from November 26 through December 1.

Background

With environmental regulations around the world in order to limit CO2 emissions, electric and hybrid vehicles are expected to become ever more prevalent. The power modules that these vehicles use to control their electricity have been built using silicon devices, but there has been a search for alternative materials that will offer better electrical efficiency in order to achieve driving ranges on par with gasoline-powered vehicles. For that reason development has been moving forward on SiC that is usable high-voltage and high-temperature environments, and that uses less power, as one material that would be an alternative to silicon. At the same time, high-thermal conductivity and temperature tolerance in peripheral components that also include thermal dissipation materials are also in demand, as they can efficiently cut heat from SiC elements that run reliably in conditions with high temperatures of over 200degC.

Carbon nanotubes are a type of nanotechnology material in which carbon atoms are formed into a cylinder with a diameter of a few nanometers. They have attracted attention for thermal conductivity that is 10 times better than copper and have a current-density tolerance 5,000 times as great, and development of applications is advancing. Equipping nanotubes on vehicles as a next-generation heat-dissipation candidate material is demonstrating promise. (Figure 1)

http://www.acnnewswire.com/topimg/Low_FujitsuCarbonNanotubeFig1.jpg

Figure 1: Schematic drawing of carbon nanotubes as heat-dissipation sheets.

Issues

Carbon nanotubes have high thermal conductivity, which would seem to make sheets of them useful as a heat-dissipation material. However, making good use of their inherent characteristics still poses problems, and only simple applications were possible, such as combining them with existing materials.

1. Cylindrical carbon nanotubes are formed on a substrate in a manufacturing process called chemical vapor deposition, in which carbon is supplied in gas form and grows in a nanotube around metallic particles with diameters of a few nanometers, which act as seeds. Here, the variation in size of the catalyst particles, the density of the supplied gas, and the variation in temperatures across the surface of a substrate or between substrates lead to a lack of uniformity in multilayered tube length and density, especially when formed over a large area, such as a large substrate. This requires constant attention to maintain consistent synthesis conditions in the manufacturing process.

2. Because the carbon nanotubes formed on a substrate are not stable and do not maintain their shape when separated from the substrate, sheet-forming methods are typically used in which they are mixed with a fixing agent, such as resin or rubber. But fixing agents, which have low thermal conductivity, reduce the temperature tolerance and conductivity of the sheet. So it becomes necessary to increase the strength of the sheet without using fixing agents.

About the Newly Developed Technology

Two technologies resulted in the development of carbon nanotube sheets with high thermal conductivity, compared to that of conventional materials, at a rate of 80 watts per meter-kelvin (W/mK), even when including contact resistance.

The newly developed technologies are as follows.

1. Multi-walled carbon nanotube growth control

In order to align the direction of carbon nanotubes with the direction of heat removal, Fujitsu Laboratories developed a carbon nanotube manufacturing process in which the temperature and pressure for nanotube synthesis were precisely controlled with respect to the metal-particle catalyst, and the position of the feedstock gas inlet was adjusted relative to the substrate so that a dense, uniform array of carbon nanotubes grew perpendicularly. (Figure 2)

2. Multi-walled carbon nanotubes sheet formation

Fujitsu Laboratories developed a technology in which the carbon nanotubes thus formed are heat treated at temperatures above 2000degC, maintaining the tube array in an orientation with high thermal conductance while forming it into a sheet. This made it possible to create a pure carbon nanotube sheet with high thermal conductivity and heat tolerance without the use of fixing agents, such as resin or rubber.

http://www.acnnewswire.com/topimg/Low_FujitsuCarbonNanotubeFig2.jpg

Figure 2: Image of multi-walled carbon nanotubes synthesized all over the surface of a 200-mm silicon substrate (left) and carbon-nanotube sheet (right).

http://www.acnnewswire.com/topimg/Low_FujitsuCarbonNanotubeFig3.jpg

Figure 3: Graph of characteristics. For comparison, actual measured thermal conductivity of conventional thermal interface materials such as indium, resin-based sheets and thermal grease are shown.

Results

A carbon-nanotube heat-dissipation sheet created by this technology was found in actual measurements, with contact resistance taken into account, to have roughly three times the thermal conductance of indium sheets, an existing material known to have high thermal conductivity. (Figure 3) Furthermore, indium sheets have a melting point of approximately 160degC, but this heat-dissipation sheet was found to have a high heat tolerance of more than 700degC. These characteristics enable the efficient cooling of power modules in advanced electric and hybrid vehicles.

Future Plans

Fujitsu Laboratories will further improve the thermal conductivity of carbon-nanotube heat-dissipation sheets, and pursue development for commercialization with the aim of having sheet products for vehicles from fiscal 2020. The company will also consider expanding the business into new areas, such as in applications for next-generation high-performance computing and telecommunications equipment.

(1) Pure Carbon-Nanotube Sheets

These are developed without resin or rubber

About Fujitsu Laboratories

Founded in 1968 as a wholly owned subsidiary of Fujitsu Limited, Fujitsu Laboratories Ltd. is one of the premier research centers in the world. With a global network of laboratories in Japan, China, the United States and Europe, the organization conducts a wide range of basic and applied research in the areas of Next-generation Services, Computer Servers, Networks, Electronic Devices and Advanced Materials. For more information, please see: http://www.fujitsu.com/jp/group/labs/en/.

Contact:Fujitsu Laboratories Ltd.

Devices & Materials Laboratory

E-mail: nanocarbon@ml.labs.fujitsu.com

Fujitsu Limited

Public and Investor Relations

Tel: +81-3-6252-2176

URL: www.fujitsu.com/global/news/contacts/

Source: Fujitsu Ltd

Sectors: Electronics, Enterprise IT

Copyright ©2025 JCN Newswire. All rights reserved. A division of Japan Corporate News Network. |

Latest Release

Honda Newly Launches "Discover Honda" Content Curation Media Platform

Dec 26, 2025 17:34 JST

|

Mazda Selected for A List in CDP Water Security for the First Time

Dec 26, 2025 17:19 JST

|

Fujitsu Develops Fujitsu Kozuchi Physical AI 1.0 for Seamless Integration of Physical and Agentic AI

Dec 26, 2025 14:04 JST

|

Establishment of DOCOMO Innovation Fund IV, a Corporate Venture Investment Fund

Dec 26, 2025 13:53 JST

|

The General Incorporated Association Generative AI Japan Announces the Winners of the Japan Generative AI Award 2025

Dec 26, 2025 11:00 JST

|

BCQ (01963.HK) to Pay RMB 585 Million Cash Dividend, Driving Share Price and Yield Upside

Dec 25, 2025 18:23 JST

|

Tohoku University and Fujitsu utilize Causal AI to discover superconductivity mechanism of promising new functional material

Dec 23, 2025 14:58 JST

|

Toward an Athlete- and Planet-Friendly Hakone Ekiden: All Vehicles Provided for the 2026 Race Will Be Electrified

Dec 23, 2025 03:18 JST

|

MHI Group to Accelerate Development of Digital Talent

Dec 23, 2025 02:57 JST

|

MHI and EXEO Group Build and Begin Commercial Use of Japan's First GPU Servers with Two-Phase DLC

Dec 23, 2025 02:20 JST

|

MHI Participates in Demonstration Testing of Vehicle-Infrastructure Integration System for Autonomous Buses in Shimotsuke City

Dec 19, 2025 03:24 JST

|

NEC and emaratech Collaborate on Biometric Smart Gates Supporting UAE Airport Operations

Dec 19, 2025 03:06 JST

|

Fujitsu to showcase mobility and physical AI tech at CES 2026

Dec 19, 2025 02:42 JST

|

Kirin and Fujitsu elucidate a novel gut-brain axis mechanism of citicoline for the first time worldwide through AI-based analysis and experimental validation leveraging drug discovery DX technology

Dec 19, 2025 02:06 JST

|

TANAKA PRECIOUS METAL GROUP and TANAKA MIRAI Lab. Released Their Fourth Collaborative Musical Work with Sound Wellness Lab (Della): "Precious Metal Orchestra - A Musical Voyage through the Sound of Precious Metals for Christmas" now available for streaming

Dec 18, 2025 22:00 JST

|

SAKENOVA: 28-Year-Old Master Brewer Pioneers AI-Driven Sake Revolution, Achieving 40% Cost Reduction While Winning International Gold Medals

Dec 15, 2025 23:00 JST

|

NEC Provides Vehicle Management Equipment for Autonomous Driving at Tokyo International Airport

Dec 15, 2025 19:41 JST

|

NEC and AEROTHAI Elevate Air Traffic Safety with Advanced Time Sync Solutions from Adtran Oscilloquartz

Dec 15, 2025 19:04 JST

|

Olympus Triples Venture Capital Fund Investment to Strengthen MedTech Leadership

Dec 15, 2025 08:30 JST

|

HKTDC 4Q25 Export Confidence Index: 2026 Hong Kong Export Growth of 8-9%, Sustained AI product demand lays solid foundation for future expansion

Dec 12, 2025 23:15 JST

|

More Latest Release >>

|