|

Fujitsu Develops Easy to Handle, Flexible Nanotube Adhesive Sheet Technology with High Thermal Conductivity

KAWASAKI, Japan, Apr 17, 2020 - (JCN Newswire) - Fujitsu Laboratories Ltd. today announced the development of the world's first adhesive sheet composed of carbon nanotubes with extremely high thermal conductivity of up to 100 W/mK (watt per meter per Kelvin)(1).

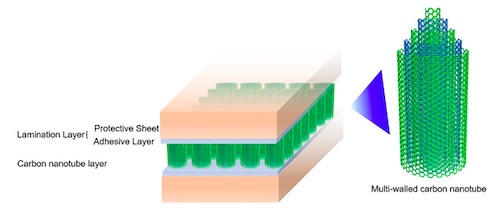

| | Figure1: Internal structure of carbon nanotube adhesive sheet |

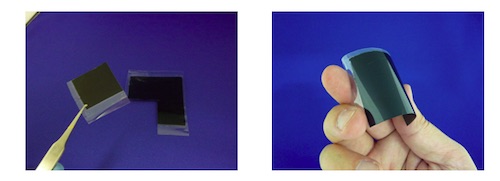

| | Figure 2: Carbon nanotube adhesive sheet |

Carbon nanotubes have high thermal conductivity and represent a promising candidate for heat dissipation from heat sources including semiconductor devices. Nevertheless, the material remains difficult to handle due to its fragility, rendering it impractical for many purposes. To address this, Fujitsu developed a technology for laminating vertically aligned carbon nanotubes, while maintaining their original characteristics of high thermal conductivity and flexibility, as well as a technology for bonding them with sufficient adhesion. This technology facilitates the cutting and handling of carbon nanotube sheets, making it possible to use them as a heat dissipation material, for example, in automotive power modules for electric vehicles (EVs).

Fujitsu aims to license the use of its newly-developed carbon nanotube adhesive sheets to companies in the materials and electrical industries, and will continue to support their use in a variety of commercial applications.

Background and Development

EVs are increasingly being put to practical use as efforts to regulate greenhouse gases accelerate throughout the world. Despite this, the fact that EVs are more expensive than gasoline-powered vehicles and lack similar driving ranges continues to hinder their widespread adoption. In order to improve the cost-performance and driving range in recent years, efforts have been made to develop semiconductor devices that use silicon carbide or gallium nitride as an alternative material to the more commonly-used silicon to reduce the size, weight, power consumption, and cost of power modules for electric vehicles. In order to make this a reality, however, countermeasures to deal with heat generated around semiconductor devices due to module miniaturization must be resolved, and components such as heat dissipation materials and bonding materials that make up modules must be designed to achieve unprecedented levels of heat resistance and thermal conductivity.

Challenges

Carbon nanotubes, a type of nanotechnology material made from carbon atoms, have thermal conductivity that is about 10 times higher than copper. One potential use of this material is its use as a heat sink for dissipating heat from heat sources like semiconductor devices. In 2017, Fujitsu developed a high thermal conductivity sheet using carbon nanotubes, but in order to maintain the sheet shape, the sheet is sintered and molded at an ultra-high temperature of 2000 degrees Celcius or higher, which results in a material that is inflexible. A hard sheet can be attached to flat materials, but it is not suitable for joining materials together that are uneven, which inhibits the places in which the sheet can be applied. Furthermore, in areas around semiconductor devices where reliability is essential, it is necessary to bond both the semiconductor and heatsink via a heat dissipation sheet consisting of carbon nanotubes in order to follow the change in shape caused by temperature differences before and after the device is operated. In general, carbon nanotubes are made adhesive by mixing them into an adhesive material such as resin or rubber, forming a sheet. However, because these adhesive materials have low thermal conductivity, it has been extremely difficult to achieve sufficient levels of both thermal conductivity and adhesion.

About the Newly Developed Technology

Fujitsu has developed the world's first carbon nanotube adhesive sheet that exhibits extremely high thermal conductivity of up to 100 W/mK even when interface resistance is included. The features of the developed technology are as follows.

Sheet Laminate Technology Fujitsu has developed a technique for laminating vertically aligned carbon nanotubes while maintaining the alignment. The laminate layer consists of two layers, a protective sheet and an adhesive layer, and has a laminate structure in which the laminate layer protects the top and bottom of carbon nanotubes. Carbon nanotubes are difficult to use as heat dissipating materials because they easily lose their shape. However, this technology protects the carbon nanotubes themselves with a laminate layer, making them stable in shape and making cutting and handling easier, which was difficult with conventional technologies.

High-Thermal-Conductivity Sheet Bonding Technology The adhesive layer that makes up the laminate layer is made of a polymer that is several microns thick. Because even a small amount of resin can cause large thermal resistance, it has become an issue that must be solved to achieve both adhesiveness and thermal conductivity. Thus, by optimizing three or more correlation parameters, such as the density of carbon nanotubes, the type and thickness of the resin, and the bonding conditions, utilizing knowledge of thermal resistance at the interface between carbon nanotubes and resins cultivated over many years, it becomes possible to bond carbon nanotubes while maintaining sufficient adhesive properties without impairing thermal conductivity.

Effects

The newly developed carbon nanotube adhesive sheet has thermal conductivity of up to 3 times that of the conventional indium heat dissipation material, which is known as a high thermal conductivity material, compared with measured values including interface resistance. Since the sheet is laminated with adhesive and protective layers, it can be easily cut and handled, and can be used for applications requiring adhesion (Figure 2). These technologies will make it possible to put carbon nanotubes into practical use as heat dissipating materials, including in automotive power modules for EVs.

Future Plans

Going forward, Fujitsu Laboratories will license the use of its carbon nanotube adhesive sheets to companies in the materials and electrical industries. and will continue to support their commercialization and practical use.

(1) W/mK (watt per meter per Kelvin) Unit for measuring thermal conductivity.

About Fujitsu

Fujitsu is the leading Japanese information and communication technology (ICT) company, offering a full range of technology products, solutions, and services. Approximately 132,000 Fujitsu people support customers in more than 100 countries. We use our experience and the power of ICT to shape the future of society with our customers. Fujitsu Limited (Code: 6702) reported consolidated revenues of 4.0 trillion yen (US $36 billion) for the fiscal year ended March 31, 2019. For more information, please see www.fujitsu.com.

About Fujitsu Laboratories

Founded in 1968 as a wholly owned subsidiary of Fujitsu Limited, Fujitsu Laboratories Ltd. is one of the premier research centers in the world. With a global network of laboratories in Japan, China, the United States and Europe, the organization conducts a wide range of basic and applied research in the areas of Next-generation Services, Computer Servers, Networks, Electronic Devices and Advanced Materials. For more information, please see: http://www.fujitsu.com/jp/group/labs/en/.

Fujitsu Laboratories Ltd.

Devices & Materials Research Center

E-mail: nanocarbon@ml.labs.fujitsu.com

Source: Fujitsu Ltd

Sectors: Electronics

Copyright ©2025 JCN Newswire. All rights reserved. A division of Japan Corporate News Network. |

Latest Release

Honda Newly Launches "Discover Honda" Content Curation Media Platform

Dec 26, 2025 17:34 JST

|

Mazda Selected for A List in CDP Water Security for the First Time

Dec 26, 2025 17:19 JST

|

Fujitsu Develops Fujitsu Kozuchi Physical AI 1.0 for Seamless Integration of Physical and Agentic AI

Dec 26, 2025 14:04 JST

|

Establishment of DOCOMO Innovation Fund IV, a Corporate Venture Investment Fund

Dec 26, 2025 13:53 JST

|

The General Incorporated Association Generative AI Japan Announces the Winners of the Japan Generative AI Award 2025

Dec 26, 2025 11:00 JST

|

Tohoku University and Fujitsu utilize Causal AI to discover superconductivity mechanism of promising new functional material

Dec 23, 2025 14:58 JST

|

Toward an Athlete- and Planet-Friendly Hakone Ekiden: All Vehicles Provided for the 2026 Race Will Be Electrified

Dec 23, 2025 03:18 JST

|

MHI Group to Accelerate Development of Digital Talent

Dec 23, 2025 02:57 JST

|

MHI and EXEO Group Build and Begin Commercial Use of Japan's First GPU Servers with Two-Phase DLC

Dec 23, 2025 02:20 JST

|

MHI Participates in Demonstration Testing of Vehicle-Infrastructure Integration System for Autonomous Buses in Shimotsuke City

Dec 19, 2025 03:24 JST

|

NEC and emaratech Collaborate on Biometric Smart Gates Supporting UAE Airport Operations

Dec 19, 2025 03:06 JST

|

Fujitsu to showcase mobility and physical AI tech at CES 2026

Dec 19, 2025 02:42 JST

|

Kirin and Fujitsu elucidate a novel gut-brain axis mechanism of citicoline for the first time worldwide through AI-based analysis and experimental validation leveraging drug discovery DX technology

Dec 19, 2025 02:06 JST

|

TANAKA PRECIOUS METAL GROUP and TANAKA MIRAI Lab. Released Their Fourth Collaborative Musical Work with Sound Wellness Lab (Della): "Precious Metal Orchestra - A Musical Voyage through the Sound of Precious Metals for Christmas" now available for streaming

Dec 18, 2025 22:00 JST

|

SAKENOVA: 28-Year-Old Master Brewer Pioneers AI-Driven Sake Revolution, Achieving 40% Cost Reduction While Winning International Gold Medals

Dec 15, 2025 23:00 JST

|

NEC Provides Vehicle Management Equipment for Autonomous Driving at Tokyo International Airport

Dec 15, 2025 19:41 JST

|

NEC and AEROTHAI Elevate Air Traffic Safety with Advanced Time Sync Solutions from Adtran Oscilloquartz

Dec 15, 2025 19:04 JST

|

Olympus Triples Venture Capital Fund Investment to Strengthen MedTech Leadership

Dec 15, 2025 08:30 JST

|

HKTDC 4Q25 Export Confidence Index: 2026 Hong Kong Export Growth of 8-9%, Sustained AI product demand lays solid foundation for future expansion

Dec 12, 2025 23:15 JST

|

Honda to Launch New Heritage Service Business

Dec 12, 2025 20:31 JST

|

More Latest Release >>

|