TOKYO, Apr 25, 2024 - (JCN Newswire) - Mitsubishi Heavy Industries, Ltd. (MHI) has started operation of a test module of the Solid Oxide Electrolysis Cell (SOEC), a next-generation high-efficiency hydrogen production technology, at Takasago Hydrogen Park*, located within its Takasago Machinery Works in Takasago City, Hyogo Prefecture in west central Japan. SOEC is based on technology for the previously developed Solid Oxide Fuel Cell (SOFC). In addition to its advantage of high efficiency, the use of MHI's proprietary tubular cell stack supports development as a technology capable of operating at high pressures, setting it apart from competing systems. The test module with a capacity of 400 kW was designed and manufactured based on the technology adopted for the SOFC, following development of core technologies at the Nagasaki Carbon Neutral Park (Nagasaki City). The system was installed at the Takasago Hydrogen Park, and started operation. The results of this research will be utilized to support even higher output and greater capacity.

400kW class SOEC test module

400kW class SOEC test module

The SOEC test module comprises a module with multiple cartridges of 500 cell stacks bundled together. During test operations, the electrolytic efficiency of the module was 3.5 kWh/Nm3 (101%-HHV (higher heating value)), confirming that the module was operating with high efficiency. This is a major step forward toward achieving MHI's goal of building a system with an overall efficiency of 90%-HHV.

At Nagasaki Carbon Neutral Park, MHI has also successfully conducted cartridge tests under larger amounts of electric current condition per cell stack, steadily making progress toward development of a "megawatt class" SOEC with high power density. In addition, MHI plans to install a megawatt-class SOEC system demonstration facility at Takasago Hydrogen Park within the next few years, and is moving forward with preparations for integrated verification within the park, with the aim of commercialization of the system following actual operation.

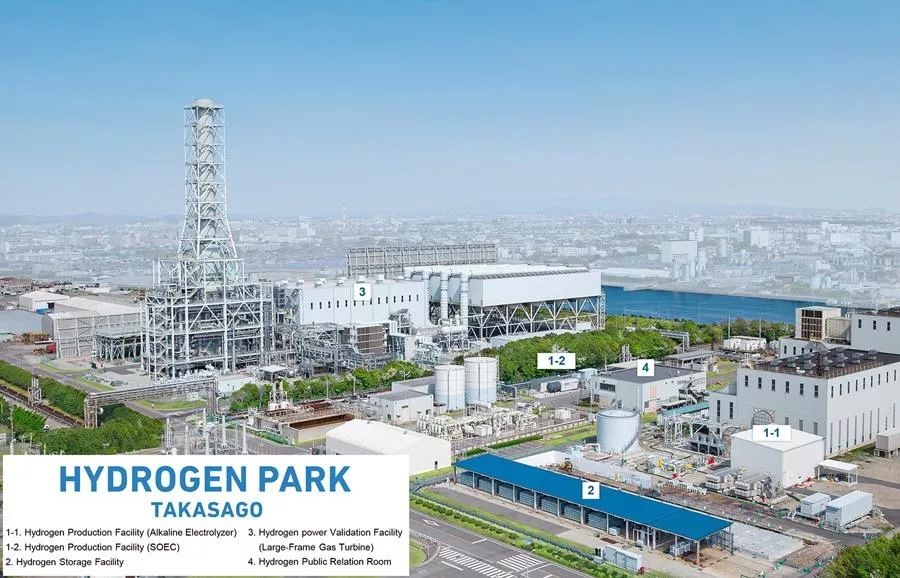

Takasago Hydrogen Park is the world's first facility with the capability for integrated verification of hydrogen technologies, from production to power generation. It is divided into three areas according to functions for hydrogen production, storage, and utilization (power generation). In the hydrogen production area, an alkaline electrolyzer manufactured by Norway's HydrogenPro AS, which has one of the world's highest hydrogen production capacities at 1,100Nm3/h, was put into operation in September 2023. The hydrogen storage area is equipped with a storage facility with total capacity of 39,000 Nm3, part of a project subsidized by Japan's New Energy and Industrial Technology Development Organization (NEDO). In November 2023, using hydrogen produced and stored in the park, MHI also successfully conducted a demonstration operation of 30% hydrogen fuel co-firing using a state-of-the-art J-series Air-Cooled (JAC) gas turbine at the gas turbine combined cycle (GTCC) demonstration power plant (commonly known as T-Point 2, rated output of 566 megawatts) located in the hydrogen utilization area. In 2024, MHI plans to conduct a 100% hydrogen-firing demonstration using a small- to mid-sized H-25 gas turbine (40 MW class) that had been previously installed for compressor driving at the combustion test facility in the park.

Going forward, in the hydrogen production area of Takasago Hydrogen Park, MHI plans to proceed with demonstrations aimed at the commercialization of hydrogen production equipment with different characteristics, such as anion exchange membrane (AEM) water electrolysis and methane pyrolysis. In addition, in the hydrogen storage area, MHI will further expand its facilities with construction to increase the total capacity of the hydrogen storage facility to 120,000 Nm3, which is about three times the current capacity, in preparation for the demonstration operation of a JAC-type gas turbine using a 50% hydrogen fuel co-firing using the JAC gas turbine at T-Point 2.

Takuya Murase, Senior Fellow, Senior General Manager for the GTCC Business Division of Energy Systems and Head of Takasago Machinery Works, said: "The expectations placed on Takasago Machinery Works, both internally and from society at large, to implement MHI Group's MISSION NET ZERO and achieve carbon neutrality by 2040, are higher than ever. The year 2024 marks the 60th anniversary of Takasago's founding. We will continue to pursue the energy transition with Takasago Hydrogen Park at the core of our efforts, and make further leaps forward."

MHI Group is pursuing the Energy Transition as an engine for corporate growth based on its MISSION NET ZERO declaration aiming to achieve carbon neutrality by 2040. Utilizing Takasago Hydrogen Park, MHI Group will accelerate the development of hydrogen production and power generation technologies and verification of systems, and by providing highly reliable products, will continue to contribute to the stable supply of electricity worldwide and the rapid realization of a carbon neutral world.

Takasago Hydrogen Park

Takasago Hydrogen Park

*For more information about Takasago Hydrogen Park, see the following press release:https://www.mhi.com/news/23092003.html

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.